How to make a chaise lounge with your own hands drawings. Simple deck chair made of boards

A dacha plot should not be considered only as a place of permanent labor “slavery”. At the dacha and during a country holiday, you will need a folding chair - a chaise lounge. This type of furniture is comfortable, laconic and functional. Folding chair You can make it yourself and use it to spend your free time pleasantly.

Useful information

Two French words longue and chaise, combined into one - a chaise lounge, the literal translation of which is “long chair”. Most often, such pieces of furniture can be found on the beaches of sea resorts, along the sides of swimming pools. You can also use a sun lounger in summer cottages, on long-distance trips, on picnics, etc.

A sun lounger should not be confused with sun loungers, which are a favorite place for sunbathing near the sea. The difference between these two types of furniture lies in the names themselves. A lounger is furniture for lying on, essentially a bed, only less comfortable. This design is lower and wider than a chaise longue.

“Long chair” is an object with a back, like an armchair, and with an elongated seat - a place to place the legs at full length. Sun loungers, like armchairs, can have armrests; the backrest can take different positions by adjusting the angle of inclination.

Functions

The popularity of the sun lounger among vacationers is associated with its functional features. A chaise longue is:

- A remedy for resting the spine and adjacent muscles. In the reclining position, the back muscles, which are heavily loaded by summer residents in the garden beds, relax as much as possible.

- Comfortable furniture, easily folded and carried (or transported) from one place to another.

- A piece of furniture in which the backrest can be adjusted from a sitting to a lying position.

- Part of the design solution summer cottage, verandas or terraces. The country house next to which such furniture stands looks beautiful and stylish.

- A place for relaxation for people of different sizes. Reliable designs can withstand up to one hundred kilograms of live weight.

Constructions

There are several design features sun loungers:

- classic folding ones (with reclining backrest);

- anatomical;

- hanging;

- in the form of a rocking chair.

Traditionally, chaise lounges are a structure in the form of a chair-bed, the upper part of which is similar to the back of a chair (armchair), and the lower part is like a small sofa. The advantage of such models is the ability to change the position of the backrest.

To make it easier to move wooden sun loungers, some types are designed with wheels that can easily transport them to any relaxation spot.

Modern industry produces anatomical sun loungers, whose manufacturers strive to reproduce the natural curves of the human body. How comfortable and practical they are can be judged by the people who bought such pieces of furniture.

Some designers like to experiment with the shape of sun loungers, but not everyone can afford to buy such models. If you are ready to amaze your guests with the bizarre shapes of such furniture, then you will have to shell out a fairly large sum.

The suspended mounting of the chaise lounge provides it with one more additional function- the ability to swing. This design is attached to a metal frame with a reliable lock, so it is very reliable. This structure is installed in a shady place (under house sheds or near large spreading trees) or an additional detail in the form of a small canopy is built in its upper part. Swinging in such a lounge chair is pure pleasure!

The stable and solid support of the “long chair” can be replaced with rounded hoop legs. In this case, the chaise lounge will serve as a rocking chair. This model is also not tied to a specific place, so this chaise lounge can easily be folded and moved to another part of the countryside or the place where you are relaxing.

Photo gallery: types of sun loungers

A metal frame with a fabric base makes this design especially lightweight

A metal frame with a fabric base makes this design especially lightweight  Relaxing in such a chaise lounge can be combined with rocking like on a rocking chair

Relaxing in such a chaise lounge can be combined with rocking like on a rocking chair  Relaxing and swinging are the main functions of this design.

Relaxing and swinging are the main functions of this design.  this design follows all the curves of the spine and resting on it is pleasant and useful

this design follows all the curves of the spine and resting on it is pleasant and useful

Connecting parts

The appearance of the “long chair” may vary depending on how the connections of the structural parts are made.

Taking this parameter as a basis, sun loungers can be divided into structures:

- In the form of a monolith (a rigid, strong connection of all components. In this model, it is impossible to change the angle of the backrest and it is difficult to carry the chaise longue due to its heavy weight).

- Monolithic-mixed (the presence of insert elements gives the structure a more beautiful appearance, but still does not add mobility).

- Folding (the use of special mechanisms and components gives such sun loungers the ability to easily and quickly transport and change the position of the backrest).

- In the form of a frame with fabric (a durable fabric is stretched over an aluminum, plastic or wooden frame).

A chaise longue can be purchased in a store, or you can make it a real “landmark” of your suburban area by applying your skills and efforts. Independent construction Even the most inexperienced craftsmen can make this piece of furniture.

Choosing material

The material preferred by those who like to lie on a sun lounger is wood. Wooden sun loungers are environmentally friendly, easy to use and not too expensive.

In addition to wood, completely different materials can be used for a sun lounger:

- plastic;

- rattan, wicker, hemp;

- wooden pallets;

- logs;

- corrugated cardboard;

- fabric with wood or metal frame;

- plywood.

Photo gallery: using different materials for chairs

Instability to climate change and heavy loads are compensated by the originality of the design

Instability to climate change and heavy loads are compensated by the originality of the design  By choosing this option you can save a lot of money

By choosing this option you can save a lot of money  Such a creative place to relax will become a real decoration of a suburban area.

Such a creative place to relax will become a real decoration of a suburban area.  Comfortable, lightweight and mobile option for a chaise longue

Comfortable, lightweight and mobile option for a chaise longue  Using plywood, you can build a sun lounger of an unusual shape.

Using plywood, you can build a sun lounger of an unusual shape.  The environmental friendliness of the material used makes this design very popular

The environmental friendliness of the material used makes this design very popular  Plastic is suitable for sun loungers installed near natural bodies of water and in swimming pools

Plastic is suitable for sun loungers installed near natural bodies of water and in swimming pools

Characteristics of materials

Each of these materials has its own pros and cons.

Table: characteristic features of materials for a chaise longue

| Chaise lounge material | Advantages | Flaws |

| Wood |

| In the absence of special treatment, it is subject to rotting; there are not many options for the shape of the structure. |

| Metal | Durable construction with simultaneous lightness. Not heavy weight design is achieved most often when using aluminum frame with fabric center. | It is necessary to have welding skills when creating a frame; without impregnation with anti-corrosion agents it will not last long. |

| Plastic | Lightness, unusual design solutions, does not require maintenance costs. Low price. | Plastic structures are not very durable and do not withstand the aggressive influence of the climate. It's not easy to build on your own. |

| Bamboo, rattan, hemp, wicker | Mobility, environmental friendliness, light weight. | The construction of such pieces of furniture requires skills in weaving; they can dry out under prolonged exposure to the sun and are not resistant to changes in atmospheric conditions. High price. |

| Available materials (pallets, logs, remains of bars and boards) | Cheap raw materials. Sometimes these materials are completely free. You can make a model “for yourself” by building a real exclusive. | Requires skillful hands and craftsmanship. If done incorrectly, they can be fragile and will not last long. |

| Cardboard | Availability, cost-effectiveness, ease of manufacture. | Unresistant to moisture and heavy loads. |

| Textile | Environmental friendliness (if natural material is used), mobility, lightness. | Fragility, instability to withstand heavy weight. The fabric may fade in the sun. Discomfort may occur when using unnatural materials. |

The choice of material depends on the chosen model, on material capabilities, as well as on the functions that you want to provide to a hand-made product.

When buying material for constructing a sun lounger, do not try to save much, because your safety and comfort depend on the strength of the structure. If you like fabric coverings, purchase durable and natural materials - tarpaulin, linen, cotton with a strong weave of threads, denim, canvas. Also use reliable fastenings to connect parts - thick ropes, carabiners, etc.

A wicker product will last longer if you prepare the vine correctly or buy raw materials for weaving from trusted manufacturers. This material is quite expensive, but how pleasant it will be to use such a design for a long time. When preparing raw materials for weaving yourself, try to study all the information about it or consult with the craftsmen. If you have macrame skills or know how to knit, then you can weave the central part of the chaise lounge from strong threads.

The metal tubes that you want to use to create the frame should not be very worn; check them for the presence of rust. Processing by special means will help extend the life of metal pipes. Old frames (for example, from folding beds) or pipes cut to the required size can be used.

The wooden components must be perfectly smooth, so don’t be lazy to sand them in advance. When purchasing wooden raw materials, make sure that the material is free of resin areas, otherwise relaxing on a lounge chair with resin may be ruined.

You should not choose improvised materials based only on their cheapness. Be sure to think about the safety of their use. The environmental factor should also be taken into account.

Making drawings

In order for the structure to be strong and the product to look great (without distortions or other flaws), it is necessary to first build a diagram and make a drawing of the future structure.

Internet resources offer a large number of ready-made schematic images of sun loungers with marked dimensions. You can use them by adjusting the parameters to suit your idea or take the entire drawing.

Photo gallery: drawing options

If you want to surprise everyone, take note of this drawing

If you want to surprise everyone, take note of this drawing  Sitting comfortably in a chaise lounge of this design, you can fully relax

Sitting comfortably in a chaise lounge of this design, you can fully relax  After studying the drawing, you can build furniture for two people to relax

After studying the drawing, you can build furniture for two people to relax  A wooden frame and durable fabric are necessary to create such a structure.

A wooden frame and durable fabric are necessary to create such a structure.  Use this drawing for a slatted chaise lounge design

Use this drawing for a slatted chaise lounge design

We prepare the tools and count the amount of material

Materials and tools for self-made chaise lounges may vary depending on the model chosen.

Let's give an example for a chaise lounge made from mixed materials of wood and fabric. For a fabric chaise lounge with a wooden frame you need to prepare:

- two meters of durable fabric (denim, canvas, canvas) fifty centimeters wide;

- pairwise wooden slats 0.25 by 0.6 cm (corresponding to this length - 110, 120 and 62 centimeters);

- slats made of wood (oak, birch, beech) 2 by 2 centimeters (one 65 cm long, and two 50 cm each)%

- PVA glue or any other furniture glue.

Tools that will be useful:

- drill;

- electric or hand saw;

- sandpaper with the smallest cross-section;

- needle file;

- square;

- roulette;

- nuts, bolts of suitable sizes or other fasteners.

If you build a chaise longue from other materials, the quantities and tools used will be different. Welding machine, an angle grinder will be needed for metal products; structures made of rattan, jute, and wicker will “require” the use of special devices for weaving.

Before starting work, try to find as much information as possible on making sun loungers with your own hands and only then get to work.

How to make a sun lounger out of wood with your own hands: progress of work

Let's talk about the process of constructing a “long chair” from wooden material. Wood is the most affordable and environmentally friendly material. It can be freely purchased without special costs. Many people who like to create something with their own hands can work with wood.

So, it’s time to move from words to action.

Stage 1. Marking and preparation of frame components.

To do this, we need to saw off four boards with the following parameters: 400 * 2.5 * 8 cm. We will also need three bars 400 * 5 * 10 cm. We also need two fixing pins.

It is advisable to sand all wooden parts of the frame and coat them with a special impregnation against rot and mold.

Stage 2. Frame construction.

This frame is made from wooden beams according to the diagram.

Stage 3. Making a place for sitting/lying.

First, we cut boards of sixty centimeters. The number of such blanks can be different and depends on the size of the gap between the boards. Typically, for a standard chaise lounge size of 60*200 cm, it takes about thirteen boards while maintaining a distance of one centimeter between them.

Using a screwdriver, we attach the boards to the frame, trying to maintain the parallelism of the arrangement of the wooden pieces.

Stage 4. Installation of legs.

We choose the length of the legs to be 35 cm, but you can make the chaise lounge a little lower (if desired).

We duplicate wooden blocks of the required length and secure them at the headboard and at the feet. In principle, the legs on the side of the head can be made single.

Stage 5. Creating a backrest.

The back frame should fit freely into the structure that we built earlier. We make the frame with the following parameters - two parts 88cm each and three parts 39cm each. Don’t be surprised that there are gaps around the perimeter of the backrest inserted into the frame; this is necessary for the backrest to recline freely.

We attach slats of the required length to the back frame. This can be done across, both on the main part, and along, as in the figure. Try to embed the screws in the “body” of the wood to make using the sun lounger safe. To improve aesthetic appearance top part the slats can be rounded.

Stage 6. Attaching the back to the base.

To firmly fasten the back and base together, you need to drill through holes in these parts, moving 9 cm down from the edge. Insert the mounting pins and secure them.

Stage 7. Construction of the support mechanism.

For support, you need to cut grooves in the main structure - two on each side. The first is at a distance of nine centimeters from the pin with dimensions of 5 by 10 cm. The second notch is cut twenty centimeters from the first, its dimensions are slightly smaller - 5 by 5 cm.

The backrest position is adjusted in this model using a wooden beam 60 cm long, which is installed in the first (half-sitting position) or second (half-lying position) grooves.

You can adjust the backrest tilt using other simple mechanisms. For example, based on the principle of folding a cot.

Stage 8. Product finishing.

Finishing work can be carried out according to your ideas or use the materials that you have on hand. Painting, varnishing, decoupage - all this will change the appearance of the chaise lounge and increase its service life.

There are other ways to make a sun lounger with your own hands. You can use a metal frame from an old folding bed and build a chaise lounge with your own hands. Detailed Description all manipulations - in a fascinating video on this topic.

Video: how to convert an old folding bed into a chaise lounge

Finishing

The main thing that needs to be considered in the process of making a sun lounger yourself is to increase its service life. This can be facilitated by special processing of the materials used in the construction of the structure. To do this, you need to use a grinding machine, sandpaper, anti-corrosion and antiseptic agents, which can be selected individually for a specific model.

Such processing can be carried out in advance, without assembling the structure. This “event” can be held after the construction of the sun lounger is completed. In this case, the protection of materials will be combined with decorative works: painting, varnishing. Choose high-quality covering materials, then your “long chair” will last a long time and delight you with its beauty.

What else can be done to change the appearance of the sun lounger? You can use textile elements: pillows, mattresses. It is best to make them removable so that you can put them away when it rains and wash them when dirty. Another option is to make mattresses and pillows from washable fabrics.

Choose the colors of the fabrics at your discretion, but it is better to use durable and dense ones. Another criterion for choosing a material is that it must be hypoallergenic and pleasant to the body, because relaxing on a sun lounger involves exposed areas of the body. You can build a bolster pillow and strengthen it in the upper part of the chaise longue for maximum rest of the cervical spine.

A canopy in the form of an awning and a light transparent fabric that protects vacationers from insects will not interfere with the appearance of the sun lounger and will improve its functional characteristics.

An additional element in the form of armrests will add comfort to vacationers.

And this original rocking chair is equipped with a special device for charging phones and tablets.

Care of the finished product

The durability and functionality of a chaise lounge will largely depend on proper care for it. What may be included in such manipulations:

- timely painting;

- updating the varnish;

- lubrication of backrest folding mechanisms;

- washing textile items.

A DIY chaise lounge is best stored indoors for the winter. This will help you use the product for many years.

Making a sun lounger yourself is a slow process, but creative and interesting. Construction of a portable comfortable place relaxation will become a pleasant experience, and the result will delight you and your guests for many years. The main thing is to take a responsible approach to making a sun lounger with your own hands.

Do you want to make your holiday in the garden or dacha even more comfortable? Then use one of the many ideas and build a sun lounger with my own hands. In this article we will talk about what material to choose for creating this type of garden bench, and how to properly assemble the structure with your own hands. We will also compose step by step instructions for making a sun lounger at home.

Variety of materials for making a sun lounger

If you literally translate the word “chaise longue” from French, you will get a “long chair”, for the manufacture of which they most often choose natural wood. But along with this material, plywood, durable fabric, plastic and wicker, etc. are actively used. Some craftsmen decorate their area with rocking chairs made from corrugated cardboard and logs. As practice shows, the production of this type of garden furniture can be approached creatively, using elementary, improvised materials that are no longer useful on the farm. The table presents the characteristics, features, advantages and disadvantages of wood, plywood, fabric as a material for a do-it-yourself sun lounger.

| Materials for making a sun lounger | |

| Tree | When choosing a wooden material, you need to pay attention to its structure and the species from which it is produced. Experts do not recommend buying spruce because of the smell of resin, which will only worsen when exposed to sunlight. It is better to use ash and larch as a base; they are characterized by strength, durability and ease of processing, and therefore not a difficult installation process. It is worth understanding that prices for natural wood are quite high, so save on this material it won't work. Wooden furniture needs to be treated antiseptics, since without proper care it quickly succumbs to rotting and deformation. |

| Textile | A feature of fabric furniture is its environmental friendliness and safety. Such structures are relatively light in weight and are extremely mobile. Along with these advantages, the following disadvantages can be identified: fragility, instability to ultraviolet radiation. Fabric sun loungers are not able to withstand heavy loads. For comfort it is best to choose natural materials, without various additives and pigments. |

| Plywood | Quite common building material, which is actively used for the manufacture of a variety of furniture, including sun loungers. For this purpose, one of the varieties of FC plywood is purchased; it is intended for interior decoration and does not contain toxic impurities. Structures made from this material are lightweight and have affordable prices. However, plywood products cannot be called durable, and they are not suitable for heavy people. |

Craftsmen with weaving skills can use wicker, bamboo, and rattan as materials for a chaise lounge, which make the furniture visually attractive, mobile and safe. As a rule, ready-made structures of this type are characterized by a high price. The downside of wicker products is their instability to precipitation and prolonged exposure to sunlight.

On modern market There are many ready-made sun loungers made of plastic, which vary in price, shape, type (monolithic, portable). Plus plastic products can be called insignificant weight and variety design ideas, embodied in manufacturing. The disadvantages of plastic rocking chairs are fragility and instability to aggressive climatic conditions.

The strength of the structure is distinguished by the sun loungers, the frame of which is made of metal and treated with anti-corrosion agents. When using aluminum, the structures are light and practical. In combination with a metal frame, fabric materials are most often used.

Variants of chaise lounge drawings

On the Internet, on sites related to the construction industry, there are various options drawings of a sun lounger. Garden furniture for relaxation on wheels, with a canopy, with an adjustable backrest, etc. will become indispensable after a hard day at work and will allow you to relax with a mug of tea or reading a good book.

Regarding appearance, sun lounger designs are usually divided into three categories:

- soldered with inserts;

- monolithic;

- portable.

Monolithic models are structures that cannot be disassembled, as they consist of solid elements. They have an attractive appearance and can be decorated with a variety of inserts made from combined materials. As a rule, monolithic sun loungers are characterized by their strength, relatively large weight, and rather large dimensions. The disadvantage of such products is the non-adjustable headboard and backrest.

Portable designs are those that can easily change the position of the backrest, etc. This type of product is considered mobile and very convenient; they are called a progressive option. Due to their folding capabilities, this type of sun loungers is easy to transport. Any of the above structures can be supplemented with mattresses or original pillows, which will provide a comfortable rest.

To make a sun lounger at home, beginners can use already ready-made projects and drawings, which the Internet is rich in, and which have been tested in practice. For example, original version it is considered to assemble a Kentucky chair (from blocks) with your own hands, as well as a chaise lounge from wooden beams, which will take a little time to produce.

Features of making a simple wooden deck chair with your own hands

The most common dimensions of sun loungers, which can even be called standard, are 60 by 190 cm. Next, we will look at the process of making a simple wooden rocking chair with a flat base, but with an adjustable back. Wooden furniture For this purpose, it most often has quite a lot of weight, which makes it difficult to move it around the site, but this problem can be solved at home, for example, by attaching roller wheels to the legs.

So, to make a wooden sun lounger with your own hands, you need to purchase and prepare the following tools and materials:

- wooden beams and boards;

- galvanized screws;

- drill;

- jigsaw;

- roulette;

- drills and screws;

- hammer;

- corner;

- brush and varnish.

The work of assembling a wooden folding chair can be carried out in several stages, which include:

- making the base;

- covering the frame with wooden gratings;

- fixing the support legs.

Now let's look at each of the stages in more detail, but first we will answer the most common question among home craftsmen: How to properly mark a tree with your own hands? So, marking wood is needed in order to significantly reduce the percentage of material waste, that is, to use it as rationally as possible. To do this, the master must have a drawing that shows in detail the constituent elements of the structure and their exact dimensions. To mark, the master needs to prepare a sheet of graph paper and draw on it necessary details, then the workpiece is transferred to thick cardboard, cut out and marked on the contours according to wooden material. The cut elements must be sanded and treated with antiseptics in order to significantly extend their service life.

To make a base for a wooden sun lounger, you will need beams, the cross-section of which should be 45*45 centimeters, and the diameter of the drills will be 40 millimeters. The installation process must begin by preparing two long and two short sidewalls. They connect with each other metal corners and screws. Next, the outer side of the base is sheathed with cut wooden gratings, the number of which varies relative to the length of the frame. Not the least place in this matter is occupied by the processing of parts and fasteners for making a sun lounger with your own hands. On long planks, at equal distances, places for the legs are marked; they are made of a wooden block, to the bottom of which wheels are attached using screws. An adjustable backrest on a DIY wooden chaise lounge can be made using a door hinge.

To do this, the lattice is divided into two groups: the first plays the role of the head, the second the base. A transverse rail is used as fastening. After the structure is completely assembled, the craftsman needs to use a grinding machine and treat the deck chair with it, and then use a brush to open it with varnish and let it dry completely. The result is a ready-made, comfortable, adjustable chaise lounge of our own production.

Features of making a fabric chaise lounge with your own hands

Fabric sun loungers are very popular among consumers, which, due to their folding design, are very convenient to use. As practice shows, many craftsmen make such products with their own hands, bringing to life a wide variety of ideas, turning home relaxation into a holiday. Due to their light weight, fabric sun loungers are easy to fold and carry around the area, take with you to the beach, etc.

The frame for a fabric product can be made of either wood or metal. Let's consider both options. To assemble a product for this purpose, you will need the following materials and tools:

- wooden beams (oak, birch or beech);

- nails;

- sandpaper;

- drill and drill bits;

- PVA glue;

- durable fabric (denim, camouflage, etc.);

- roulette;

- bolts;

- round sticks.

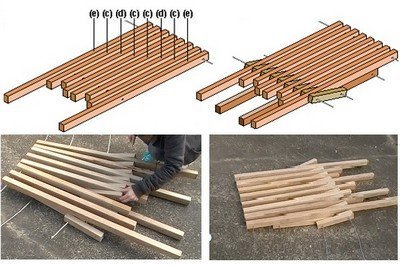

Step-by-step instructions for making a sun lounger with your own hands in in this case looks like this:

1. To assemble the base of the sun lounger, three frames are prepared different sizes: first - 1200 mm*600 mm, second - 1100 mm*550 mm, third - 650 mm*620 mm. Holes are made in them, through which the structure will be connected.

2. First, the first and third frames are connected, bolts and round sticks are used to fasten them, then the first and second workpieces are fastened, the joints are treated with glue.

When choosing a fabric base, you should pay attention to its composition, manufacturer, structure and quality. It is necessary that the selected material is durable and natural, this will extend the service life homemade sun lounger. The master has the opportunity to purchase the base of the desired color, maximally embodying his own state of mind and mood. Also portable, a fabric chaise lounge can be a great addition to your home decor.

Many beginners are interested in the question: how to properly assemble a structure with a metal frame with your own hands? Why is this option no less popular? The fact is that the metal base is maximally adapted to changing positions and is easily subject to various upgrades. Finished products of this type are quite compact, they are easy to remove and store when not needed.

The assembly of a chaise lounge with a metal frame is practically no different from the previous, wooden version, only in this case you will need not beams, but metal frames, for the manufacture of which it is better to use steel or aluminum. Do not forget about treating the material with anti-corrosion agents, otherwise rust will soon appear, which will not only spoil the appearance of the product, but also damage the fabric base.

To ensure that fabric sun loungers retain their original qualities long time, professionals recommend using a variety of impregnations that provide protection from the active effects of ultraviolet radiation, repel moisture, etc. Typically, such remedies last up to 4 weeks.

How nice it is after a hard day at work to retire to the garden or sit on the lawn by the pond in order to relax, unwind and enjoy the sounds of nature. What piece of garden furniture do most people associate with comfortable relaxation? Yes, a lawn chair! Comfortable portable extended chair in addition to the straight one functional value will act as a spectacular element of the exterior, emphasizing the style of the summer cottage. There is nothing difficult about making a garden sun lounger with your own hands. We have selected for you several options for easy-to-make sun loungers. It won’t be difficult to choose among them suitable model, which anyone can build.

This chaise lounge can be safely used instead of a bed: a flat surface, an adjustable backrest. What else do you need for an afternoon relaxation?! The only drawback of this design is that it is very problematic to move it around the site yourself.

Sun loungers of this design are very popular among vacationers on sea coast, and among owners of suburban areas

But there is a way out! We suggest considering the option of a chaise lounge equipped with rollers. To make a sun lounger you need to prepare:

- 18 mm thick slabs of laminated spruce wood;

- Wooden beams 45x45 mm (for the frame);

- Boards 25 mm thick for cladding the sides;

- Jigsaw and screwdriver;

- Drills with a diameter of 40 mm for wood work;

- 4 mounting brackets for beds;

- Countersunk head screws;

- 4 rollers 100 mm high;

- Sanding sheet, grit 120-240;

- Varnish or paint for woodwork.

Slabs of the required size can be purchased at a carpentry workshop or at construction market. When choosing slabs, it is better to give preference to products made from coniferous trees, since they are more resistant to precipitation.

The size of the sun lounger depends on the wishes of its owner. In most cases, the design is made with dimensions of 60x190 cm. Having decided on the dimensions of the sun lounger, we make two long and two short sides from wooden blocks. We assemble the structure frame from them, securing them together using fastening corners. We cover the outer side of the frame with boards.

On long slats at a distance of 5-8 cm from the corner, we attach the legs of the chaise lounge, the material for the manufacture of which was bars 5-10 cm long

We fix the legs to the boards using screws 60 mm long.

We mount the wheels: we install rollers in the center of the short legs of the chaise longue, fixing them with screws 30 mm long, equipped with semicircular head 4 mm in diameter

To make a wooden lattice, use a jigsaw to cut boards measuring 60x8 cm from the slabs.

We attach the slats to the bed using self-tapping screws, leaving a gap of 1-2 cm. To maintain the gap, it is most convenient to use special spacers

When planning to make a chaise lounge with an adjustable backrest, the lattice should be divided into two parts: the lounger and the headboard. We place both parts on connecting boards and fasten them together using a door hinge.

To arrange the fastening strip between the long beams of the chaise lounge frame, we fix the transverse rail. We fix the support stand on the mounting strip, fixing it on both sides with screws

The finished chaise lounge can only be processed using a grinding machine and opened with varnish or paint.

We invite you to watch a video that shows how this chaise lounge model is assembled:

Option #2 – fabric chaise lounge on a frame

Another equally popular chaise lounge model that can be folded into an almost flat shape.

It is convenient to move a light chair around the site, choosing open sunny meadows for relaxation, or, on the contrary, shaded corners in the garden hidden from prying eyes

To make a folding chaise longue you need to prepare:

- Rectangular slats with a thickness of 25x60 mm (2 parts 120 cm long, two 110 cm long and two 62 cm long);

- Round slats with a diameter of 2 cm (one piece is 65 cm long, two are 60 cm long, two are 50 cm long);

- A piece of durable fabric measuring 200x50 cm;

- Nuts and furniture bolts D8 mm;

- Fine-grained sandpaper and round needle file;

- PVA glue.

It is better to make slats from hardwood species, which include birch, beech or oak. To make a sun lounger, it is better to use fabrics that are highly durable and resistant to abrasion. For example: canvas, tarpaulin, denim, mattress teak, camouflage.

Cut the slats to the required length. By using sandpaper carefully sand the surface.

According to the diagram, where A and B indicate the main frames, B represents the stop-regulator, we assemble the main structural elements

In the long slats of the main frames, at a distance of 40 and 70 cm from the corners of the structure, we drill holes with a diameter of 8 mm, and then grind them using a round needle file.

So that you can change the position of the backrest in the chaise lounge, we make 3-4 cutouts in frame B at a distance of 7-10 cm. To arrange the seat, we drill holes with a diameter of 2 cm, stepping back from the two ends of the slats. We install crossbars into the holes - round slats, the ends of which are pre-lubricated with PVA glue.

Let's start assembling the sun lounger: we connect parts A and B using screws inserted through the upper holes. Using the same principle, we connect parts A and B, only through the lower holes

The frame is assembled. All that remains is to cut out and sew the seat. The length of the cut is determined by the possibility of folding. A cut that is too short will not allow the chaise longue to fold, and a cut that is too long will sag when folded down. To determine the optimal length, you need to fold the lounge chair and measure the fabric: it should be slightly stretched, but without force.

We nail a piece of fabric with processed edges to the round slats located on parts A and B. To do this, we wrap the edge of the cut around the crossbars, and then fix them with small nails with thick heads. An option is possible in which “loops” are made at the edges of the cut and put on the crossbars.

Option #3 – Kentucky folding chair

The original chair is assembled entirely from blocks. If necessary, the chair can always be folded and stored.

The advantage of this garden chair the fact that when disassembled it does not take up much space, while the design is designed in such a way that it allows you to completely relax your muscles

To make a chair we will need:

- Wooden blocks measuring 45x30 mm;

- Galvanized wire D 4 mm;

- 16 pieces of galvanized staples for fixing the wire;

- Fine-grained sandpaper;

- Hammer and wire cutters.

For making a chair, bars measuring 50x33 mm are also quite suitable, which can be obtained by sawing a 50x100 mm board into three equal parts. Total length bars should be 13 meters.

Instead of galvanized wire and staples, you can use galvanized studs, the edges of which are secured with eight nuts and washers.

To determine the required quantity and length of wooden blocks, it is convenient to use a summary table. According to the drawing, we make through holes

The diameter of the holes should be 1.5-2 mm greater than the thickness of the wire used. Having prepared required quantity bars, you should carefully process all the edges, sanding the surface with fine-grained sandpaper.

Let's start assembling the structure.

For clarity, we use the assembly diagram of the seat with dividers, as well as the back of the chair. The dotted lines indicate the locations of through holes with wire threaded through them.

On flat surface According to the diagram, we lay out the bars for arranging the seat. Pass wire through through holes

Using the same principle, we assemble seats with dividers, connecting wooden blocks with pieces of galvanized wire

The main structural elements have been assembled. We take the ends of the wire, holding the sides of the structure, and carefully lift the chair.

All that remains is to cut off the excess wire with wire cutters, and then bend and secure the ends with galvanized staples

Chaise lounge for the garden: 8 DIY models

The garden chair is ready. If desired, it can be coated with a semi-matte woodworking varnish. This will significantly extend the service life of such a popular element of garden furniture.

On at the moment There are a huge number of variations for making a wooden sun lounger with your own hands. Some of them will be discussed below.

Wooden lattice chaise lounge

This model of sun lounger is very common at seaside resorts. Now the owners country houses and dachas will be able to enjoy relaxing on such a piece of furniture. The chaise longue is essentially flat, with an adjustable backrest. The only thing that makes it difficult to move around the site is its heaviness. But the problem can be solved by installing rollers or wheels on it.

To assemble this piece of furniture with your own hands you will need:

- Plates with a thickness of 1.8 cm;

Important! It is best to use slabs made from coniferous wood, as they are more resistant to atmospheric influences.

- For the frame, beams size 45*45;

- For covering the sides of boards 2.5 cm thick;

- Screwdriver and jigsaw;

- For working with wood, several drills with a diameter of 4 cm;

- Screws (it is better to take those that have a countersunk head);

- Mounting corners for the bed in the amount of 4 pieces;

- Ten-centimeter rollers in the amount of 4 pieces;

- Sanding sheet with grit from 120;

- Decorative coating (varnish, paint).

The master himself can independently choose the size of the chaise lounge that suits him best. The standard size is 60*190 cm. To begin with, it is best to prepare drawings.

The algorithm for making a sun lounger with your own hands is as follows:

For more information on how to make a sun lounger out of wood with your own hands, watch the video:

Wooden chaise lounge with fabric seat

This chair is also very popular. It is convenient in that it is very convenient to move this piece of furniture around the site; it does not cause any problems during transportation and storage, as it folds into a compact flat shape. Making such a chaise lounge with your own hands is not difficult.

For such a chaise lounge you will need:

- 6 slats with rectangular cross-section one size 25*60 cm, but different lengths: 2 x 120 cm, 2 x 110 and 2 x 62 cm.

- Five slats with a round cross-section of 2 cm. The number depends on the length: 65 cm - 1 piece, 60 and 50 cm, two slats for each length.

Important! Slats should be used from wood species such as birch or beech. They have greater strength.

- Durable fabric measuring 200*50 cm. Canvas, jeans or tarpaulin are perfect.

- Bolts and nuts for furniture with a diameter of 8 mm.

- PVA glue.

- The file is round.

The work is performed in the following sequence:

At this point, the work on assembling the frame is completed, now we move on to sewing the seat. Before this, you need to measure how long to take a piece of fabric. To do this, you need to fold the chaise longue and measure the amount of fabric. In this position, it should sag a little and not be tense.

In order to fix the fabric on the chaise longue, you first need to process the edges on sewing machine, and then wrap the transverse round crossbar and nail them with small nails. On both sides.

It is also possible to make loops on both sides and attach the fabric on them to the cross bars.

Kentucky folding chair

This original chair is assembled from blocks, folds easily and does not take up much space when stored.

To make it you need to prepare:

- Bars size 45*30. Size 50*33 cm is also used.

- Galvanized wire with a cross-sectional diameter of 4 mm or studs with washers and nuts.

- Staples for clamping wire in the amount of 16 pieces.

- Fine-grit sandpaper.

- Wire cutters and hammer.

For work, the total length of the bars is 13 meters. All cuts and holes in the bars must be carefully sanded.

The work is carried out in the following sequence, as shown in the drawings:

Conclusion

Chaise lounge - very comfortable furniture, which gives home comfort and a certain charm to the area. It is a pleasure to relax in such a chair.

No need to buy regular ones for the plot plastic chairs that look too simple or buy expensive garden furniture, just take a little time to create your own unique pair of sun loungers, so you can save your budget and develop your carpenter skills, and make original decoration plot with your own hands, which will later be a source of pride. You can make several sun loungers of the same type, or you can try your hand at making all the models at once and place them throughout the garden so that you can relax anywhere.

Approaching summer season and it's time to think about creating a sun lounger with your own hands. It will allow you to enjoy your outdoor recreation to the fullest.

Chaise longue in French means long chair. This is a chair for relaxing. It can, at the owner’s request, change the position of the backrest.

Sun loungers are widely used on beaches and by pools. On personal plots, dachas.

Sun loungers are made from various materials:

- wood;

- plastic;

- aluminum;

- rattan;

- PVC pipes;

- durable fabric.

Wooden sun loungers are the most popular and environmentally friendly. They come in a variety of shapes and designs. The disadvantage of monolithic wooden sun loungers is their weight. But this problem can be solved with the help of wheels.

Plastic sun loungers are characterized by easy mobility, ease of maintenance, and relatively low cost. Their minus is their fragility.

Fabric loungers are versatile and comfortable. Their frame is made of wood, metal or PVC pipes. They fold easily and do not take up much space.

Rattan sun loungers look great in the lap of nature. They are environmentally friendly. However, purchasing them is expensive. If you have sufficient skills, you can simply weave a rattan lounger yourself.

In this article we will tell you how to create wooden sun loungers with your own hands.

To ensure the longevity of the effort expended, the materials used must be processed.

Antiseptics and special impregnations will help protect wood from moisture, harmful insects, rot, and mold. It is better to carry out processing before assembling the structure.

After installing the sunbed, the wooden parts should be coated with primer, drying oil, varnish or paint. This will extend the life of your masterpiece.

Fabrics should also be protected from rain and sun. Water-repellent impregnations will help preserve their brightness and service. Their effect lasts 2-4 weeks.

And, of course, remember the famous Russian proverb when working. Measure seven times, cut once.

Monolithic chaise lounge made of wood

Solid models are heavy. Therefore, to make it easier to carry, wheels are added to the headboard. The following instructions will help you make a chaise lounge on wheels with your own hands.

You will need tools:

- electric jigsaw or hacksaw;

- drill;

- screwdriver;

- self-tapping screws;

- fine grain sandpaper;

- spirit level;

- roulette.

When choosing a tree, pay attention to conifers. They are sold at affordable prices, are characterized by increased water resistance.

Materials needed for a sun lounger:

- glued slab made of wood, its thickness should be 2 cm or more; at least 2 cm thick.

- boards 0.25 cm thick.

- wooden beam with a square section of 50x50 mm;

- 4 wheels with a diameter of 10cm;

- corners for strengthening the bed;

- door hinges;

- varnish or paint.

We suggest you make a chaise lounge according to this pattern.

Legend:

- Front legs.

- Hind legs.

- Bearing longitudinal.

- Back support.

- Back support.

- Bearing transverse.

- Fixing bar.

- Backrest support.

- Wheels.

- End beam.

- Back slats.

- Seat slats.

- The support beam is transverse.

- Fixing bar.

You can independently determine the size of the desired sun lounger and make calculations. Or use standard size 60x190 cm. It is the most optimal and ergonomic for the average adult.

Assembling a chaise lounge on wheels

We assemble the base frame from the bars. We secure the load-bearing parts with corners similar to those that secure the base of the bed.

We sheathe the resulting frame with pre-prepared and sanded boards.

We make blanks for the legs from timber. Their height usually ranges from 5-10 cm. Choose one that is comfortable for yourself and your household.

We drill holes with a drill, retreating 5-7 cm from the ends of the longitudinal sides. We secure the legs with long bolts. We control the horizontal side with a spirit level.

We screw the wheels to the center of the legs with bolts with a diameter of 30mm.

Let's start cutting the lattice elements. Use a hacksaw or jigsaw to cut 8x60cm boards.

Using self-tapping screws and a screwdriver, screw the slats to the chaise lounge frame. Since the boards are not screwed tightly, we use spacers to obtain even gaps.

We should have two parts. The smaller one is intended for the headboard. Connecting both grids door hinges. We install a support bar under the opening part.

All that remains is to sand off the production flaws. Apply wood primer. Paint it in your favorite color and the chaise longue with your own hands is ready.

For more comfortable rest You can sew additional mattresses that fit the size of the bed.

Simple sun lounger

To create a wooden chaise lounge with your own hands, you need the following materials, as well as tools:

- tape measure and square;

- pencil;

- saw;

- electric drill;

- screwdriver or screwdriver;

- screws, self-tapping screws and studs for fixation;

- sandpaper or grinder;

- wood putty;

- dye.

Wooden beams used in the work:

- for the back of the chaise lounge, take boards 5×10 with a length of 88 cm - 2 pieces, 39 cm - 3 pieces, 60 cm - 1 piece;

- 2 longitudinal bars for a frame 215 cm long;

- 2 cross beams -50 cm;

- 6 legs -35 cm;

- 13 slats for a seat measuring 2.5 x 8 x 60 cm;

- 6 slats for the back - 2.5? 8? 88 cm.

The first priority is to create a very strong frame. We take two parts 215 cm long, connect them with screws to half-meter transverse parts.

Let's move on to sitting. Take all the 60 cm slats. Attach them to the frame with self-tapping screws, leaving small gaps. To ensure that the gaps are even and uniform, use spacers 1 cm thick.

We create the legs of the lounger. To give maximum stability to the chaise longue, two legs are nailed at once at the legs. One at a time at the head. The instructions indicate bars with a height of 35 cm. But you can choose a height that is comfortable for you

We make the back from 2 boards measuring 88 cm and 3 boards measuring 39 cm. The resulting frame should easily fit into the base, leaving a small gap between the structures.

We securely fasten the longitudinal strips. We round them for a more beautiful look.

Attach the backrest to the base of the lounger. To do this, you need to drill holes at a distance of 9cm from the edge of the seat. Secure with pins.

We make 2 grooves at the base of the sun lounger for the support bars. The first 5x10 cm notch should be approximately 9 cm from the stud. The second is 20cm from the first. But its depth will be only 5x5 cm.

A 60cm beam is inserted horizontally into the first recess. To change the position, the board is transferred vertically to the second recess.

Sand all rough edges and imperfections. Process it. Cover with paint or varnish. The chaise lounge is ready with your own hands.

DIY garden lounger video

Fabric chaise lounge

A chair with a frame complemented with fabric is one of the most comfortable, budget types of chaise lounges. It is convenient to fold and easy to carry. Can be stored in flat view. It takes up little space.

To create a sun lounger with your own hands you will need:

- bolts, nuts with a diameter of 8 cm;

- small nails with round heads;

- round sticks (1 piece -65cm, 2 pieces - 50cm, 2 pieces -60cm);

- rectangular bars 25x60cm thick (2 pieces 120cm, 100cm and 60cm long);

- needle file, fine-grain sandpaper;

- glue;

- durable material measuring 200 by 50 cm.

Choose materials carefully so that your work is not in vain. Bars from rocks solid wood perfect for a lounger. Choose:

- birch;

- oak;

- beech.

Choose fabrics with maximum strength. Great fit:

- teak for mattresses;

- tarpaulin;

- canvas;

- camouflage;

- denim

These materials have increased wear resistance and will last you a long time. Let's move on to creating a sun lounger with our own hands. The base consists of three frames:

- A.1200x600 mm.

- B.1100x550 mm.

- H.650x620 mm.

Cut the boards to the required length. We sand with sandpaper.

In the longitudinal bars we make indentations of 70 and 40 cm, and drill holes with a diameter of 8 mm with a drill, just like the bolts. Sand with a round file.

We make cutouts in part B. They will allow you to change the position of the back later. To do this, retreat 7-10 centimeters. It is necessary to cut 3 or 4 recesses. We polish well.

According to the diagram, we drill holes in the bars to connect the parts.

Assembling the base of the lounger. We connect frames A and B using screws. Then we connect frames A and B. For greater reliability, we lubricate the ends of the round slats with PVA before assembly. The frame of the sun lounger is ready.

Now you need to sew the seat. Place the material on the bed in the folded position. The fabric should be slightly stretched. Measure the desired length. Hem the edges. This way you will increase the wear resistance of the material. The chair will look neater.

We attach the fabric base to the lounger. We wrap round slats on parts A and B. We nail them with small nails with round heads. The chair is ready.

ADVICE. The edges of the fabric base can be made in the form of loops. In this case, the seat is simply strung on slats.

DIY fabric chaise lounge. Model 2

For this chair you will need:

- wooden slats measuring 2x4 cm. Two slats each with a length of 122cm, 112cm, 38cm. One piece each 61 cm, 65 cm, 57 cm. And four slats 60cm long;

- slats measuring 2x6 cm. One each 61 and 57 cm;

- 65cm wooden rod with a diameter of 1.2cm;

- a piece of fabric 137 cm long and 116 cm wide;

- bolts, washers, nuts, screws;

- glue;

- round needle file, sandpaper or grinder;

- electric drill.

Manufacturing process:

Process all the details of the future chair in advance. Sand them using a machine or fine-grained sandpaper. Cover with special impregnations that protect the wood from corrosion. Appreciate your work.

Pay attention to the drawing. The crossbars at the bottom of the legs help fix the position of the backrest. Make them. Or cuts, retreating from the edge by approximately 20, 25, 30 and 35 cm.

Drill holes for the bolts in the back frame. To do this, measure 41cm on each side.

On the seat frame, step back 43cm from the top. Make holes.

On the piece supporting the back, drill holes in the center of the edges.

Process all holes with a round file.

Model installation

First assemble the back frame. A beam 61 cm long will carry a large body load. Secure it as securely as possible. Leave a small gap between the two slats. The tissue will be fixed through it.

Assemble the seat. Fold it with the back frame. Be sure to place a washer between them. Bolt the frames together.

ADVICE. To prevent the nuts from loosening quickly, tighten an additional lock nut on top. For greater reliability, attach the nuts to glue, varnish or paint. First tighten the nut. Then loosen it slightly so that the parts rotate freely.

Install the back support piece using washers and bolts.

Sand away all imperfections. If desired, varnish or paint.

Fold the fabric in half, sew, retreating 1.5 centimeters from the edge. Turn it inside out. Fold the edge of the material for the rods that secure the panel between the slats. Sew.

Now insert the material between the slats. Secure with a rod. This installation model allows you to remove the fabric for washing without much effort.

Chaise lounge made of polyvinyl chloride

Another example of a lounger with a fabric base. Only in this case, wooden slats are replaced with PVC pipes. Chair sizes may vary.

In this do-it-yourself chaise lounge model we used:

- 2-inch polyvinyl chloride pipes;

- L-shaped connectors – 8 pieces;

- T-shaped connectors – 6 pieces.

Connect first for the vertical bar PVC pipes lengths 30 and 45cm using a T-connector. Place L-shaped connectors on the ends. Connect the second vertical in the same way.

Now you need to connect the two sides together. Please note that one horizontal crossbar is solid. Its length is 66cm. It is attached closer to the T-shaped connection, which in turn should be directed into the structure. The second side consists of two 30cm pipes, combined with a T-shaped adapter, turned at an angle of 45 degrees from the long side of the strip.

Don't rush. Measure pipes accurately. As a result, you should end up with a rectangular structure.

Now is the time to make the connection on which the seat will rotate. To do this, insert a 5cm long pipe into the T-shaped connector and secure it with another T-shaped adapter. It will become the basis of the horizontal frame.

Make the long sides similar to the vertical section, using 30 and 45 cm pipes with an L-shaped connector. For crossbars, use a solid tube 30cm long. And also consisting of 2 x 20 cm with a T-shaped adapter.

You did everything right if you get a rectangle within a rectangle.

The seat is located between a long section of the vertical section and a short section of the horizontal. Adjust the level of inclination that is comfortable for you. Measure the distance between the two free T-pieces. Cut the pipe to the required length. Insert the rear support.

Take measurements of the fabric consumption for your chair. Use thick fabric. For example, canvas, tarpaulin, jeans. Hem the edges and secure the fabric to the chaise lounge. Enjoy your holiday.

Portable lounge chair

The durable, lightweight chair is quickly assembled and disassembled. It is convenient to take it with you outdoors. The model is so easy to make that it is suitable even for novice craftsmen.

The collapsible chair consists of 2 parts:

- backrest covered with dense, wear-resistant fabric;

- wooden seat.

In addition to tools, the following materials are used:

- 2 legs for the backrest measuring 20x40x800mm;

- 2 legs for the seat - 20x40x560mm;

- 2 lower crossbars - 10x50x380mm;

- 1 top crossbar - 10x40x380mm;

- 1 seat crossbar - 20x40x300mm;

- 5 slats - 20x40x400mm;

- piece of material - 600x500mm.

The procedure for assembling a portable sun lounger is shown in the diagram.

First, the parts are connected using self-tapping screws and a screwdriver.

The workpiece is processed and varnished.

While the frame dries, the fabric is folded and stitched. Then it is nailed using staples and a construction stapler to a wooden piece.

We connect the back and seat of the chaise lounge.

Enjoying your holiday in your new armchair.

Pay attention to another interesting chaise lounge model in the video.

Kentucky chair

You can make the original look of a chaise lounge with your own hands. A sun lounger is assembled from bars. Convenient, easy to fold. Takes up minimal storage space.

For the chair you will need:

- 4mm galvanized wire;

- 16 staples;

- bars 30x55 mm.

Before starting assembly, it is recommended to treat the bars to protect them from ultraviolet rays, humidity. Choose an oil- and wax-based stain. Beitz is good. You can use parquet oil. Apply the product using a spray bottle or brush.

Kentucky chair installation

Drill the holes. Their diameter should be slightly wider than the thickness of the galvanized wire. Sand all rough spots and imperfections.

Fold the parts according to the photo and start stringing the boards onto the wire.

Secure it with brackets.

ADVICE. Instead of wire, use galvanized studs. They are secured with nuts and washers.

Raise the planks. The Kentucky chair is ready for use.

Original chaise lounge

Design Koalition has developed an unusual chaise lounge with a fabric canopy that will allow you to enjoy outdoor recreation even on a hot day, protecting you from the scorching sun. The cost of such a sun lounger is 5970 euros. We will tell you how to save money and make an original chaise lounge with your own hands.

To create a lounger you will need the following materials. And also tools:

- 2 sheets of plywood 2cm thick with a size of 160x180cm;

- 6 round strips with a diameter of 30mm and a length of 92cm;

- 12 planks made from leftover plywood measuring 94x10cm;

- dense fabric with a width of 92 cm;

- construction adhesive;

- screws;

- roulette;

- cardboard for layout;

- circular saw;

- electric drill.

Transfer the diagram onto cardboard or thick paper. To make the task easier, you can first draw it into squares of 10 by 10 cm. The template makes it easy to correct all the shortcomings on paper. Subsequently, you will only circle it 2 times. Or maybe you’ll get the hang of it and make a few chairs for relaxation.

We transfer the drawing onto sheets of plywood and cut out the side parts of the disk or band saw. At the junction with the round beam, we cut out recesses with a diameter of 30mm.

We sand all the unevenness and cutting defects.

We assemble a rigid structure. Lubricate the ends of the beam with wood glue or PVA. We insert the timber into the recesses and fasten it with screws. The joints can be additionally treated with glue for maximum reliability.

Now you need to put the structure on its side. Place weights on the gluing areas. And let the chaise longue dry completely.

We begin to screw the planks to the ribs of the structure. At the same time, we make a 10-12 cm long indentation between them. Tighten the screws deeper so that their heads do not cling to the fabric and tear it.

We sand the product again. Now we hide the assembly flaws.

Use wood putty to hide all the screw heads in the places where the fabric is tensioned. We paint the chaise lounge.

You probably noticed that the description only gives the approximate width of the awning. The fact is that you can decide to cover the chaise lounge entirely with fabric, or just make a canopy. Decide for yourself. Measure the dimensions and sew the awning.

ADVICE. It is better to fasten the awning with ties or Velcro. This will allow you to remove the fabric at any time and wash it without problems.

Birch lounger

It must be said that our Russian craftsmen are distinguished by their ingenuity and creative approach. This chaise lounge is made by hand from birch logs. It is distinguished by Russian folk flavor. Perfect for garden plots.

The work uses:

- logs with a diameter of 75-120mm;

- drill and set of drills;

- electric saw;

- staples and screws;

- marker;

- electrical tape or chalk for drawing.

Let's start creating a sun lounger.

We saw the trunk into logs 45 cm long.

On the floor we draw a line for the future sunbed using chalk, or glue it with electrical tape.

We lay the logs according to the diagram. We drill holes with a drill and connect the logs using long self-tapping screws. We use a socket wrench for this.

Almost turning over finished product. We are testing. We eliminate shortcomings.

For greater stability back side We fix the sunbed with staples.

A monolithic birch chaise lounge is ready to delight you and your guests.

Unusual do-it-yourself sunbed for a summer house

Pallet lounger

One of the most budget-friendly sun loungers is made by yourself with skillful hands from pallets. What is it? A pallet or pallet is a stand that is designed to transport cargo.

DIY pallet lounger video.

Now you have several options for making your own sun loungers. Choose a design that is convenient for you, or affordable. When choosing sizes, keep in mind that in addition to you, your wife and your children will also rest on the sunbed. Adjust the width and height to suit your overall needs.