How to make a rounding machine by hand. Do-it-yourself rounded log

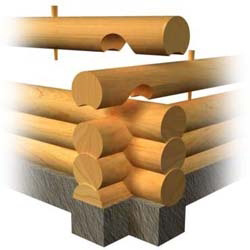

Houses, cottages, log houses, bathhouses made of rounded wood are always popular. High-quality processing cutting of wood is carried out on special machines that make it possible to obtain a log of the same diameter along the entire length.

The latest models of rounding machines perform a number of other functions, but for simple operations you can make such a unit with your own hands.

Functions

The main function that any rounding machine has is the processing of logs as a body of revolution by milling. But to assemble a log house, simply cylindrical blanks are not enough. And in this case, additional equipment capabilities will come to the rescue:

- excavation of grooves to form various locking connections;

- production of parquet dies, timber;

- sawing of linear products;

- sawing timber into a carriage and further into edged boards;

- all stages of log rounding, from roughing to final;

- removal of mounting bowls and compensation grooves.

In this case, the log itself is not reinstalled, but cutters and individual components are changed during the work. The result is parts with a wide range of diameters. The limitation concerns the length of the processed logs: the sleds are designed for seven-meter workpieces. A skillful combination of cutters and working techniques allows you to produce complex wooden structures.

Device

The installation has several main components. The bed is made in the form of a metal frame. Might have a hard time welding connection in the form of a rectangular pipe or mobile connection of individual metal elements using bolts and nuts. It is the basis for fastening all structural elements.

The rounding machine contains guides along which the sawing tool moves. They usually form a single structure with a metal frame. In certain types of installations, the log moves along guides.

There may be one or two (front and back) headstocks. Their purpose is to secure and twist the log. On the headstock in some models of machines there is a dividing head, which serves to establish a certain angle of rotation for different stages processing.

The unit for fastening tools and moving mechanisms is a caliper.

The main purpose of the cutter is to fasten the cutting tool. It also provides reduced vibration, increased accuracy of operations and ease of entry into the workpiece. There are shaped and universal cutters.

The knives of the rounding machine are made of high grade steel. The cutting tool is attached to the cutter so that it can be easily replaced or removed for sharpening.

In addition, it is installed additional elements. These are levers that make it easy to install the workpiece on the frame, and stop rollers that prevent it from sagging. There are also brakes and a carriage lock. They are used in machines with the function of removing the crown bowl and are installed at the end of the carriage. To excavate a longitudinal groove, a log rotation regulator is used.

Modern manufacturers of woodworking equipment equip such rounding machines with automated computer-controlled modules.

Classification

Experts propose to classify rounding machines according to five parameters:

- type of mechanism;

- the method of moving the log;

- level of automation;

- drive power type;

- diameter of the workpiece used (minimum – 80 m, maximum – 500 m).

Two types of mechanisms are used in installations. The first is a pass-through (rotary) one, which allows you to continuously move the wood through the cutter. The second is cyclic (turning), in which processing is performed by repeating a cycle of actions.

If cyclic actions are performed by a cutting tool, the machine is classified as a cyclo-pass type, and if a log moves, it is classified as a cyclo-positional type. In the mechanisms, logs have the ability to both rotate and move rectilinearly along the guides.

For the chosen level of productivity, it is important to consider the degree of automation of the rounding machine.

In mechanized models, the operator loads and unloads logs, configures and adjusts the mechanisms. He also monitors the quality of work performed at all stages of operations.

In automated rounding machines, the specialist servicing it is assigned the role of process controller.

In semi-automated installations, the master joins the process after the machine has completed one cycle of operations.

Pay attention! To create optimal and uninterrupted operating conditions, it is important to select the appropriate type of drive power supply.

Electric can work without interruption, provided that the power lines are reliable or there is an additional power generator. Gasoline requires constant refueling, but does not depend on external factors.

But the main choice is between pass-through and loop types. The pass-through will provide high productivity, sometimes at the expense of the quality of processing. Most models of such machines do not have the ability to make the surface of the log smooth, without burrs and roughness. Cyclic installations work much slower, but at the same time they have a number of advantages:

- provide very high quality processing;

- perform the entire set of operations;

- have compact dimensions;

- The design is stable and easy to maintain.

In addition to all of the above, price, equipment manufacturer and required processing quality play an important role.

Offers for professional work

On the woodworking equipment market there are offers of any price category and for different technical needs. The most popular models are “Sherwood”, “Termite”, “Cedar”, “Taiga”, “Terem” with full cycle functions.

Technical characteristics are presented in the table.

Stages of designing a machine yourself

Purchasing a professional installation for producing processed wood is an expensive proposition. But there is an alternative solution: you can make a machine for rounding logs with your own hands.

A sawmill is used as the base. The cone in the front part is replaced with a stop. A bearing is inserted into the tailstock. You will also need an electric motor to ensure the torsion of the log. Rotation can be manual, then you need to make a handle.

The cutter is assembled as a separate unit from a very durable material. Its movement can be ensured by laying rails. This is the path along which the cutter will move. In this design, the workpiece must be positioned along the rail and rotated so that the cutter slides along it.

Before installing the rounding machine, concreting (if not available) or compacting the area of the required size is carried out. Next, the frame sections are assembled and leveled in the horizontal plane. The maximum installation error should not exceed 0.5 mm per 1 m in all directions. Installation height 20 cm.

The subsequent assembly steps are as follows:

- installation of the power mechanism;

- installation of the front and rear headstocks so that their axes coincide and are parallel to the guides;

- fastening racks for cables for mobile power cables;

- cable tension;

- clamp-stop equipment for the power mechanism;

- grounding installation;

- connecting the motor and checking the direction of rotation of the lumber. The desired direction is regulated by changing the order of connecting the motor phases;

- mounting a shaped cutter on a conical part using bolts;

- screwing a universal cutter into the body of a figured cutter. In order to avoid imbalance, the knot is tightened with a wrench;

- checking for correct assembly.

A homemade machine requires preventive maintenance if it is idle for a long time or installed in a damp room.

The construction of a private house, cottage, or residential log house requires high-quality timber, which is processed using professional equipment. For technical buildings, you can round the wood yourself.

In this article:

All machines for the production of cylinders can be classified according to the following criteria:

- production technology;

- kinematic cutting diagram;

- type of cutting tool;

- degree of automation of the processing process.

It is by these criteria that we will consider the equipment presented at domestic market woodworking machines.

Classification according to technological schemes

Today, 3 technologies for the production of rounded logs are used:

1) Classic

The log is clamped in the center of the ends and rotates. The movable cutter removes chips, moving along the workpiece. Positional lathes operate according to this scheme.

2) Positional

The log is also fixed in the center, but is processed by a stationary rounding spindle equipped with a special rotary head. This technology was developed for rotary type positioning machines.

3) Passage

Log clamps are not used - the workpiece is moved through the rotary head by a roller mechanism. Machines operating on this principle are classified as rotary-type equipment.

Pros and cons of various technologies

Advantages of pass-through technology:

- continuous supply of logs is possible, which ensures processing speed;

- high yield rate finished products(up to 90%) is achieved by uniform distribution of the allowance in the cross section. The allowance is necessary to form a log cylinder and a circle at its ends. With this technology, this indicator is no more than 1-2 1-2 msm in diameter;

- the length of the log is practically unlimited, but the minimum size must be such that during processing the workpiece does not end up in the gap between the rollers;

- good productivity - in an 8-hour shift, about 35-40 m3 of products (100-130 logs) are produced on such a machine;

- aspiration is used to remove chips;

- versatility - these machines can produce not only rounded logs, but also edged lumber, block houses, and decorative slab boards.

Main disadvantage: the curvature of the finished part is almost identical to the curvature of the original log; It is quite difficult to compensate for this shortcoming - either ensure the loading of relatively smooth raw materials, or saw the semi-finished product into blanks 1-2 m long.

The main advantage of positioning machines is minimal curvature of the log at the exit, which allows you to work with any workpiece.

Flaws:

- the volume fraction of the output depends on the initial curvature and run of the log. For example, when processing 1st grade logs (according to GOST 9463-88), the waste rate can exceed 50%;

- the length of the workpiece is limited by the dimensions of the machine;

- lower productivity than pass-through equipment. But the problem of time-consuming readjustment in equipment with rotation of the workpiece has been partially solved - it is enough to move the support of the milling unit in the transverse direction. But when working on machines with log fixation, the complexity of setting up the tool is significant, since it is necessary to align the cutters of the cutting module as accurately as possible when changing the standard size of the raw material;

- need for qualified personnel– incorrect reconfiguration of the cutters can reduce the processing accuracy to zero.

Main disadvantage- average performance indicators - can be eliminated by installing a second milling unit on the machine, which will allow finishing and roughing to be carried out in one pass.

Profile forming equipment

The production of edges and grooves of rounded logs is carried out using saws or specialized cutters.

Depending on the type of machine and its configuration, these operations are performed either simultaneously, together with the formation cylindrical logs, or for an additional pass. Of course, the first option is preferable in terms of processing speed and overall performance.

Depending on the type of cutting tool, the cylindering process is performed:

1) Turning

The main movement is the rotation of the workpiece or tool, during which chips are formed continuously.

The cutting module can be:

- rotor(female head with a set of round cutters for roughing and finishing gouging) – optimal configuration for machines that does not cause difficulties in reconfiguration;

- through cutters(angular, oblique knives) is an effective, but outdated technology, the use of which requires the participation of a qualified specialist.

2) Milling

The main movement is rotation of the tool:

- two longitudinal cutters;

- end mills with longitudinal feed;

- conical end mills with longitudinal feed.

The most common option today is face-taper cutters. But for pass-through machines, profile ones are considered the most promising.

On a positioning machine with a movable milling unit, the profile is made after the cylinder has been formed. The rotation mechanism is blocked, cutters/saws are attached to the support. In this case, the speed of reinstallation and correct adjustment of the equipment is crucial, otherwise significant downtime will result.

On most through-type machines, milling and sawing units are available in basic configuration. They are located in the direction of movement of the log, behind the cutting module. The straightness of the edges of the grooves, as well as the formation of the cylinder itself, directly depends on the degree of curvature of the feedstock.

Despite the fact that turning is recognized as a more accurate technology for obtaining an ideal cylinder, the quality of the cut does not particularly depend on the type of machine - only on the sharpening of the tool, its correct settings and operation. It is important that the workpiece settings are maintained between operations - any reconfiguration leads to a loss of manufacturing accuracy of various structural elements. In this regard, positional type equipment with a fixed position of the log is recognized as the best. On such machines, deviations in size can only occur due to severe wear. cutting tools or insufficient rigidity of the frame structure.

Formation of “cups” - connecting mounting grooves

The “cup” element is made using a milling unit and straight guides that feed the tool. After forming the groove, the cutter returns to its original position.

Such a structural unit can be part of the process flow - the edges of the laying groove, to which the axis of the “cup” is oriented, become the supporting base. In the most common arrangement, the cutter cuts into the workpiece below the center axis.

But, as practice shows, best performance accuracy is demonstrated by positional type machines, on which the cup cutter is mounted on a support with a vertical cutter. In this case, the axis of the cup can be formed under different angles to the plane of the mounting groove. For such operation of the cup-cutting unit, it is necessary that the log is rotated along its axis and fixed in a new position.

If the rounding machine is not equipped with a cup-cutting module, equipment for cutting grooves can be purchased separately. The asking price is from 100,000 rubles.

About mechanization and automation

According to this criterion, rounding machines can be divided into 3 classes:

- automated– the entire complex of operations (including loading and feeding of workpieces) is performed by the machine;

- semi-automated– the process is automated within one work cycle. Next, only the loading/unloading of the machine is performed manually, and all other operations are performed by the machine;

- mechanized– loading/unloading, setting, and regulating the operation of the machine are performed by humans.

Today in our country, mainly mechanized machines are used, which are equipped with modules for loading/unloading, cutting and feeding. But basing, setting, controlling and regulating production process done by a person. Used and additional equipment– forklifts and transporters.

So what should you choose?

Considering that equipment with different technological schemes has almost the same level of maintenance and service costs, the main parameters by which a rounding machine is evaluated are the productivity and quality of processing of all structural elements.

In terms of the first indicator, the pass-through machine leaves behind all types of positional equipment. That is, it allows you to ensure the shortest payback period for capital costs and greater profits. True, this statement is effective only if there is stable sales and supply of raw materials. But the quality of the products leaves much to be desired: a rough surface due to shortcomings in the basing system and non-observance of straightness when using insufficiently smooth raw materials.

Regarding processing accuracy, positional equipment has the best performance, although it throughput an order of magnitude lower than through-path machines.

However, for an objective assessment, the manufacturer of any technological equipment usually provides a sample made on a given machine. The results of his examination can tell a lot.

Industrial machine for production of products high quality must be equipped with:

- massive frame;

- precise guides;

- convenient control system;

- powerful drive (7-90 kW);

- safety barriers in the cutting area.

Let's summarize: Pass-through machines are indispensable in large-scale production, where it is possible to sort raw materials. The main line of business is the serial production of ready-made building kits for the construction of wooden houses.

But for medium and small enterprises focused on working on exclusive projects, with output volumes of up to 15 m 3 /shift, and also when using raw materials with a high percentage of curvature, knots and other defects best option– positional lathe.

To commit right choice, it is necessary to have a clear understanding of the raw material base, parameters production premises And technological scheme work of future production. Since the machine must support the size range of raw burdens, be compatible with other equipment, match the planned flow rate and fit into the workshop area.

There are about 30 companies represented on today's woodworking equipment market. Therefore, knowing the parameters of “your” machine, all that remains is to decide on the manufacturer.

The rounding machine is designed for processing logs to give them the required shape. After the machines have completed their work, the logs are considered ready for use.

When choosing an OS1 400 machine, models from Sherwood or other leading manufacturers, you should know which functionality can be counted on when purchasing such a unit.

The OTS rounding machine, like its competitors and analogues, performs the following functions:

- The grooves necessary for mounting different types of logs are made;

- Logs are rounded;

- They produce edged boards based on a carriage;

- Make dies for parquet;

- Milling smooth surface wood;

- It is not edged boards that are cut;

- The crown cups are prepared;

- They make timber;

- They saw the wood into a carriage;

- Regulate the speed of rotation of the log;

- Compensation type grooves are made using a circular saw.

An important feature of woodworking machines is that equipment of this type can perform a wide range of operations without the need to reinstall the log itself. Special cutters and components with which the machine is equipped allow the production of parts on units of this type different diameters and complex configurations. The master, having at his disposal an OS1 400 rounding machine, can easily process a log with his own hands, the length of which is about 7 meters.

The price doesn't matter last role when choosing Sherwood equipment or its analogues. The same Kedr machine model OS 100 costs from 210 thousand rubles. If you want to purchase an ODS machine, get ready to pay 750 thousand rubles.

Largely due to the high cost, instead of factory equipment of this type, many people prefer to assemble a homemade rounding machine. An experienced craftsman, having drawings, is capable of constructing such a machine with his own hands. But for a beginner to take on homemade machine It is strongly not recommended if the goal is to obtain high-precision processing equipment.

Device Features

The Altai rounding machine, like its competitors, have approximately the same design. Therefore, all units of this type consist of:

- Metal frame. In most cases, it is made from rectangular pipe;

- Guide for moving the power unit and cutter;

- Grandmas. It serves to fix the log and give it rotation. The headstock is characterized by the presence of a dividing head, which allows you to fix the barrel. The spindle is also located here;

- Milling cutters. Special figure cutters select grooves for subsequent installation. A universal cutter allows you to cut crown cups, process planes and perform rounding on Sherwood machines;

- Knives for milling cutters. They are made from high-strength steel. At the same time, the design of the equipment allows you to change and sharpen the cutter blade without removing the latter;

- Lever for placing the processed log;

- Stop rollers. They protect the log from sagging;

- Mechanical brake. It should be used when selecting crown cups;

- Carriage latches. The latch stops the movement of the carriage when the bowls are being removed;

- Devices for rotating logs. The master uses the mechanism of this type to execute longitudinal groove on Sherwood machines and its analogues.

Classification

Even experienced master must conduct a detailed analysis of what type of equipment will suit him best. There are two main types of mechanisms designed for rounding logs.

- Passage. Here the machine allows you to constantly advance the barrel while processing it. The log moves as it passes through the processing cutters. The pass-through unit is used quite often, but has its own nuances.

- Cyclic. Movement and processing of wood is carried out on the basis of cyclic movements.

In this case, the cyclic unit has two subtypes:

- Cyclo passable. Here, only the cutter makes movements, and the log itself remains motionless;

- Cyclo-positional. The working tool remains stationary, and the movement is carried out by the log.

Units may differ from each other in the type of movement during the woodworking process:

- Rotational;

- Straightforward.

Do not forget that woodworking equipment can have varying degrees of automation. If we take this criterion into account, then all cylindering devices are divided into three types.

- Mechanized unit. The master must load the wood to be processed, monitor the completion of all operations, set up and regulate the operation of the machine.

- Auto. The master performs only one main task - he controls the progress of the woodworking processes. The log is loaded and processed automatically.

- Semi-automatic. Automation specially developed for the device is responsible for performing one stage of woodworking, after which the master begins his duties.

What to choose?

The main question of choice is not whether you buy a Sherwood, Termite, Taiga unit or other domestic or foreign analogues.

When choosing woodworking equipment for working with logs, the main point is whether you give preference to a pass-through device or a cyclic one.

Based on this, two objective conclusions can be drawn.

- The pass-through type of woodworking machine, which allows you to round a log, is characterized by high productivity. At the same time, the equipment allows for the formation of errors during the processing of the material. The surface may remain rough upon completion of work.

- The cyclic version of the woodworking rounding device is capable of high-quality processing of the material and performing all related processing operations. The disadvantage is the fact that in terms of performance these units are significantly inferior to their walk-through counterparts. Compact dimensions and a stable base have led to the fact that it is positional units that are most widely used in the woodworking industry.

The assortment is extensive, so the choice should be approached with all responsibility. Focus on your own needs in terms of quality, productivity and do not forget about the importance of the financial side of the issue.

All photos from the article

The construction of wooden housing in our great power has been developed since ancient times. First of all, this is caused by colossal reserves of this environmentally friendly and relatively inexpensive material. Despite the emergence of many new construction technologies, classic log houses still remain popular. After all, the advantages of rounded logs are obvious, and they will be discussed further.

Why exactly a log?

First, let's find out what a rounded log is and why the vast majority of people prefer to build housing from it.

Important: speaking in the dry language of definitions, a rounded log is usually called a straight tree trunk, pre-processed on woodworking machines to give it the correct cylindrical shape.

As a result, the top uneven layer and knots are removed, and compensation and mounting grooves are applied.

Advantages of the material

- Wood itself has a natural porous structure, making it one of the best warmth and sound insulators.

- Having clear geometric dimensions, this material fits perfectly together. Specially designed grooves ensure high tightness and quality of inter-crown seams.

- All trunks have a clearly fixed diameter, the maximum deviation here can be no more than 2 mm. This makes it possible to choose wood for the construction of premises for various purposes with specified characteristics.

- On at the moment there is simply no building material that is more environmentally friendly and beneficial for people. Unlike wood, traditional brick or modern views building materials can only boast of environmental neutrality.

- Although the price of rounded logs may be higher than that of many competitors, such houses do not require additional internal and external cladding . This material itself has natural beauty, as a result of which owners save significantly on finishing.

- Modern woodworking equipment makes it possible to initially produce trunks with ready-made connecting elements. This significantly speeds up the construction process and gives a lot of layout options.

- You may have already heard that natural wood breathes. This refers to the array's ability to take out of thin air excess moisture and give it back when conditions change. Simply put, a tree is natural conditioner, providing an ideal microclimate for human life in the house.

- And finally, the construction instructions are quite accessible. A simple bathhouse, barn or small country house, good owner if he really wants to, he can build it with his own hands.

What are the disadvantages

- As we have already said, wood is a living material, so over time the wood begins to dry out and crack. This is true, but thanks to modern technologies, such processes can be significantly slowed down.

- Many people know that during the process of growth, a tree trunk slightly twists in a spiral. After the cut, this spiral sometimes begins to unwind. This is why craftsmen do not recommend building from freshly cut timber; the structure may fail. But a dry rounded log does not have this drawback.

- Disadvantages such as high fire hazard and susceptibility to biological pests are easily eliminated using the same specialized impregnations.

- Perhaps the only significant drawback of any wooden structure is the high percentage of shrinkage of new houses. Well-dried, high-quality wood shrinks up to 100 mm for every 3 - 4 m of wall in the first year. And 10 - 20 mm each for another 2 - 3 years. Freshly cut timber will take up to 10 years to shrink.

What affects performance

To determine the basic parameters of the material, there is a set of regulations. In our country this is GOST 2708-75, in the west ISO 4480-83. There is no big difference between them, the main parameters are identical. It is on this data that a program such as a calculator for rounded logs of volume, weight, density and other characteristics is based.

All photos from the article

The history of the construction of wooden residential buildings goes back to the distant past. In those days, the most important factor in construction was the availability of building materials, which was wood.

It was easy to process and did not require the use of any special tools, which, however, did not exist. Now the wood is processed using technology and modern technologies, which predetermined the appearance of a rounded log, which we will discuss below.

Today, blanks can be made to a certain size - length and diameter. Taking into account the fact that wood has low thermal conductivity and increased sound insulation, which allows you to maintain warmth, peace and quiet in the house, the material is in demand more than ever to this day.

Classification

Currently, three types of rounded logs are available to consumers, differing in cost, as well as quality and processing technology:

| Natural humidity |

This is explained by the fact that at the first stage the house goes through a natural process of shrinkage and shrinkage. |

| Dry | Buildings constructed from such material do not require shrinkage, since it occurs during the production process. In this case, the latter consists of 2 stages:

Having gone through all stages of preparation, the workpieces are processed to final size, and then the bowl and heat lock are cut. The duration of the production process has a direct impact on the cost of the material, which is an order of magnitude higher than those logs that require a natural drying process. |

| glued | The most expensive building material of this type, this is due to the complexity of the production process. |

Processing stages

- First, the logs are sorted depending on their type and purpose.

- All rejected material is selected for further processing into lumber.

- The process of manufacturing rounded blanks is the most important stage processing. For these purposes, log rounding equipment is used - turning and milling machines, belonging to the heavy class. During processing, the logs are given the shape of a regular cylinder, and the thickness of all workpieces should be the same.

Advice: deviation is possible, but it should be insignificant, no more than 2-4 mm.

- Next is the milling of the mounting groove, designed for stability and a tighter fit of the logs in the structure.

- A compensation cut is made on each log to avoid cracking during drying.

- A rail track is necessary so as not to drag the log along the cutter manually, but it moves itself. The operating principle of such an installation is similar to a conventional one. milling machine– the cutter moves along the fixed rotating workpiece.

Foundation

- It is necessary to make a concrete platform for the machine. If this cannot be done, you can install the equipment on dense ground, securing it to the guides wooden sleepers 1.5 m long, located across the machine. Leave a distance of 1 m between sleepers.

- On a site - concrete or prepared soil - sections of the frame are installed so that each of them is located strictly horizontally and at the same level. An error is allowed, but it should not exceed 0.5-1 mm. If the site is concrete, the frame is mounted at a height of 150 to 200 mm. All joints formed during the installation process should also be concreted.

- After this, you can begin installing the power unit, as well as headstocks (front and rear) and racks, onto the frame. To secure electrical cable, pull the cable onto the racks. At the last stage, install a clamp on the power unit, and then ground the machine.

- Make sure that all phases in the power supply and on the motor are connected correctly. To do this, start the machine and check the correct operation of the cutter and the direction of rotation of the workpiece.

And if something went wrong:

- the movement of the cutter does not coincide with the control panel;

- the log is rotating in the wrong direction

the phases, both in the network and on the motor, should be swapped.

Advice: if the machine has been transported from one place to another, or is used less than once every two months, moisture should be removed from the electrical equipment before starting.

To do this, it must be kept in a dry room.

Operation

Before you start using a homemade machine, you need to check correct placement and the rigidity of the headstock fixation. This stage of work should not be skipped, as it is very important.

All headstocks must be placed parallel to the guides, and their coaxiality is measured by measuring the distance between their center and the longitudinal profile, as well as the nearest guide. The distances should not differ from each other by more than 1 mm.

Advice: to avoid damage to the equipment and the material being processed, you should check the cutters for correct balancing, and also check the sharpening angle of the knives.

Before you start using the machine for rounding logs with your own hands, you should check that the frame is positioned correctly horizontally. To do this, a gasket is placed under it, the thickness of which is equal to half the taper. In this way, you can determine how parallel the axis of the headstocks is to the plane of movement of the cutter.

Conclusion

A rounded log allows you to quickly build the necessary wooden structure– residential building or outbuilding. You can purchase ready-made building material of this type or make it on a machine converted from a sawmill. The video in this article will provide additional information on the above topic.