Do-it-yourself hive: how to make a high-quality “house” for bees without mistakes. Decorative plastic beehives and recommendations for their manufacture Manufacturing of decorative beehives for a summer cottage

We will send the material to you by e-mail

If you are an avid beekeeper or are planning to become one, then you should definitely make a hive with your own hands. This way you can save significant cash. This process will help you become more familiar with the behavior of bees and effective technologies honey production. Self-production will improve the consumer characteristics of honey and extend the life of the hive. We will talk about all the nuances of creating a house for bees in today’s review.

A high-quality hive is a reliable basis for obtaining good results

A detailed study of the life activity of bees will help create comfortable conditions for them. Below are basic knowledge, which will simplify understanding of the requirements for the main and additional elements of the hive design.

Even superficial knowledge about the families of these insects makes it possible to verify the clear organization of communities. Worker bees have a division based on functionality, which is largely determined by a certain age range.

After leaving the cell, lack of strength limits the insects' capabilities. They are looked after and fed by adults. But after 1-2 days, young bees begin their first duties. They create impeccable sanitary and hygienic conditions in the cell so that the queen can lay eggs there.

- feeding larvae;

- construction of honeycombs, clogging of filled cells, repair work;

- security;

- taking nectar;

- removing excess moisture from it and other processing procedures;

- collection of pollen, nectar, and other substances useful and necessary for life.

Honeybees have well-developed sense organs. To search for flowers and in other situations, they use vision, smell, touch, hearing, and taste buds.

They mate with drones outside the hive and lay up to several thousand eggs per day under favorable conditions. During this period, they need high-quality nutrition with a sufficiently large energy reserve per unit volume.

Of particular importance is temperature regime in a bee hive. The full development of the pupa, the intended purpose of the adult insect, depends on it. Some bees have the ability to raise their own temperature above +40°C, performing the functions of biological “heating elements”.

Here is just some information about the life of bees. But even this information is enough for preliminary conclusions:

- It is necessary to create conditions in the hive for the comfortable existence of all members of the bee family.

- Behavioral characteristics should be taken into account different sizes worker bees, drones, queens. Appropriate corrections are made when determining the dimensions of tapholes and other structural elements.

- It is necessary to eliminate or minimize strong odors, noises, and other external influences, which can cause disturbance to insects.

- Will come in handy good insulation to reduce heat loss in winter and overheating in summer.

Construction of a hive for bees: standard design, features of popular modifications

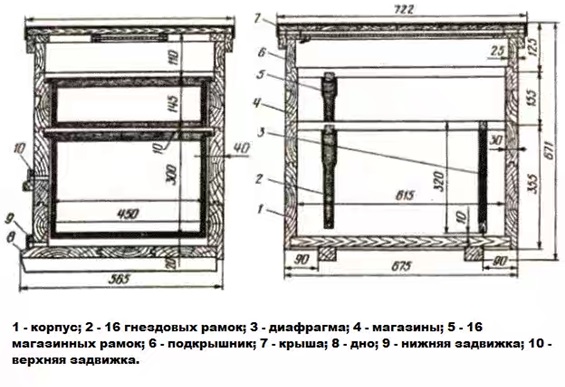

Below is the purpose and special characteristics of individual parts:

- The base (1) ensures the stability of the entire structure. It is made quite durable. Small holes in the side parts are needed for ventilation, which prevents rotting processes.

- The bottom (2) in this hive serves as a transition element and a “take-off and landing” platform at the same time. Some designs provide for the possibility of changing the size of the entrance taking into account the size of the bee colony, season, and weather conditions.

- The main part is the body (3). In this project, two identical elements are installed. This is where the queen lays eggs. To make it easier to maintain a comfortable temperature, the walls are made thicker, or an additional layer of porous materials. Frames are placed inside so that there is sufficient space at the bottom for cleaning.

- In the separator (4), the dimensions of the slots are made such that only worker bees can penetrate upward. There is a store (5) with frames where honeycombs with honey are created during bribes. Sometimes this part of the hive is used to house layers during the winter.

- A hole is made in the ceiling (6). It is necessary for ventilation and free movement of bees. Feeders are installed on this “floor”, additional elements insulation during the cold season.

- The design is completed by a cover (7). It is covered with a metal sheet on top, which protects the wooden parts from moisture.

The special shape of the side parts with the expansion of the upper part (1) helps to create gaps of certain sizes when installing products in the hive. Strings (2) made of fishing line or steel wire facilitates the construction of honeycombs. The elongated elements of the crossbar (3) rest on the walls of the housing during installation.

For your information! There are various drawings of bee hives on the Internet, so it’s not difficult to find suitable option. But it must be emphasized that professionals and experienced experts prefer collapsible structures. Such structures are more convenient to use. In particular, the repair of individual components is simplified.

This element divides the hive into functional parts. For example, you can create favorable conditions for several bee families in one structure.

For your information! Instead of plywood, polyurethane foam, chipboard, and other materials are used that meet the above requirements for parts of the hive.

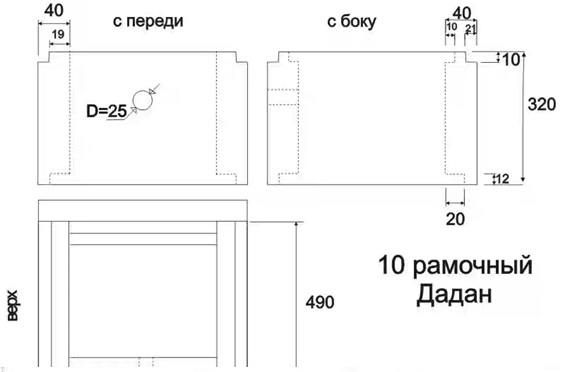

Dadan-Blatt hive: simplicity and efficiency

The clear advantage of this solution is modularity. If necessary, you can install a certain number of main buildings and stores. There will be no major difficulties during the manufacturing or repair process.

Here are the dimensions of the Dadan hive for 12 frames. The drawing is a working example that has been tested in practice. Some characteristics and details can be changed:

- The roof does not have to be flat. This option is suitable for organizing nomadic apiaries. If you make one or two slopes, raindrops are removed from the roof surface faster.

- The empty space between the bottom of the housing and the base is created from 20 mm or more for effective ventilation.

- For the walls of the case/magazine, it is recommended to take wood with a thickness of 35/25 mm. But these standards must be adjusted taking into account the climatic conditions in the region of operation.

- For any number of frames, the following distances to the bottom/side walls/top ceiling are left from them: 20/7/10 mm.

This example makes clear the advantages of improving classic solutions:

- Instead of recesses in the walls, the lower heavy part is equipped with folding metal handles for carrying.

- Built-in latches ensure secure fastening of parts. But if necessary, they can be separated without the use of special tools.

- To create optimal sizes The “input block” uses a metal strip with holes.

Important! Before changing the standard drawings of the Dadanovsky hive with your own hands, carefully study the recommendations of qualified beekeepers. This will help eliminate the mistakes that beginners make with a lack of practical experience.

Langstroth-Ruth hive: how to keep many bees without unnecessary difficulties

Like other vertical-type structures, this structure takes up little space on plot of land. If you use a minimal version, with one body and a half-magazine, it will not be difficult to organize the work correctly. However, experienced beekeepers advise not to start with installing a large hive. A large magazine will significantly increase the total volume, which will make it difficult to insulate the nest. Several floors allow you to occupy up to 40 frames, which implies great strength of the bee colony.

For your information! Professional beekeepers create hives of this type up to 7-8 floors. With their help, they collect more than 200 kg of honey in combs in one season.

Horned hive: minimum cost and simple production

Do-it-yourself drawings of a horned hive explain main feature– presence of pins in separate blocks.

Advantages:

- All parts can be made using simple carpentry tools.

- The design allows for some dimensional inaccuracy.

- Assembly and disassembly are carried out quickly and correctly.

- Inexpensive materials are suitable for production.

- Lightweight hives of this type move without much physical effort.

Alpine hive: space saving

Experts claim that the model for this type of construction was the life of a bee colony in a hollow wooden trunk.

The following information will help clarify important features such structures:

- There are no ventilation holes or grilles dividing the total volume.

- The layer of air in the ceiling area moves, which prevents the accumulation of moisture and condensation.

- During the honey harvest period, the strength of the family increases. You can install additional housings to increase productivity and maintain an optimal microclimate.

- In winter, the reverse operation is performed. This makes it easier to create favorable temperature conditions.

- The cases are divided into volumes of 4-8 frames, taking into account the size of the bee colony.

- The bottom is installed only in the lower block.

- The upper element serves as a drinking bowl and feeder.

Cassette hive: solving large-scale problems

This structure ensures year-round maintenance of bees without seasonal movements. But with appropriate equipment, transformation into a mobile version is possible.

He explains the features of the invention in the field of beekeeping, which is confirmed by a domestic patent. The authors managed to reduce the complexity of maintenance while simultaneously improving temperature conditions during the cold season:

- Single body (1) provides integrity and high strength.

- The frames (3) are installed in cassettes, which are mounted on skids.

- The protective cover (6) is installed if protection against rodents is required.

- Bee families are separated by a special panel (4).

- "Pod-cassette" (7) sections provide passage fresh air. They are taken out for routine maintenance.

- To improve the insulating properties, a layer of insulation (5) is installed.

Hive lounger: comfortable conditions for several bee families

This solution allows you to create favorable conditions for housing several families of bees.

It is better to install this part on door hinges. As shown in the figure, such equipment will facilitate manipulation of a fairly heavy part during inspection, removal finished products and performing other work operations.

Boa hive: description and important details

With the help of these drawings, it is not difficult to make a boa constrictor hive with your own hands. The following comments may also be helpful:

- Filling compact frames with honeycombs is not difficult for bees, so additional supports (metal strings, plastic threads) are not installed.

- To ensure sufficient thickness " air cushion“The height of the lid walls is 25-30 mm, no less.

- Standard case dimensions (width x depth x height in cm): 37.5 x 36 x 13.5. This volume is enough to install a maximum of 10 frames. The diameter of the hole for the tap hole is 19 mm.

Work with such hives is organized according to a special algorithm:

- In the cold season, 4-5 buildings are used.

- When spring comes, 1-2 lower blocks are removed. This procedure is combined with replacement of the subframe and preventive inspection.

- After the first effective bribe, 1-2 cases (frames with foundation) are installed.

- If necessary, additional housings are mounted on top. As finished products accumulate, they are removed to pump out honey.

The above example is one option. Beekeepers like the ability to “flexibly” organize work processes and configure individual parameters for certain conditions. They note positively the following details:

- Compactness and low weight of individual parts reduce labor intensity. One person can remove and carry them, without an assistant.

- The absence of wire increases the reliability and strength of products.

- If you follow the given dimensions, a sheet of standard foundation will be enough for four frames without unnecessary waste.

- Small volumes of housings are useful for creating optimal space for each bee colony.

For an objective analysis, it is necessary to list the shortcomings:

- A small support area reduces the stability of the structure.

- It's easy to make one frame. However, given the total quantity required, more time and effort will have to be spent compared to similar products for a typical multi-body hive.

- In small sections there is a lot of empty space that is not used for its intended purpose (to create and fill cells).

Related article:

How to make a beehive with your own hands: detailed instructions from “A” to “Z”

Before you begin to implement your plans, you need to carefully study the features of beekeeping, weather and natural conditions in the region, and other important factors. You should clarify how to make a beehive with your own hands from different materials. Will come in handy accurate estimate financial capabilities, carpentry and other professional skills. It would be correct to apply comprehensive analysis taking into account real initial parameters. It is necessary to take into account not only the main, but also associated costs and operating costs.

For the correct manufacture of hives with your own hands, dimensions, drawings, videos and other information materials in the articles are supplemented with professional comments, useful recommendations. This data will help minimize errors.

Checking different options and creating optimal hive drawings with your own hands

If the do-it-yourself drawings of bee hives found approximately correspond to the existing requirements, you need to add your own adjustments. Careful preparation will come in handy complete set design documentation:

- Check the dimensions of all parts.

- To correctly read the drawings, views with different sides, sections of complex nodes.

- It is necessary to write down what materials are suitable for manufacturing individual elements, are there any alternative options?

- You should check the technologies for creating blanks and the assembly process step by step.

- Next, make a list of necessary purchases.

- This list is used for preliminary price checking. If necessary, make appropriate replacements.

For your information! If necessary, new professional skills are learned in advance. It will be useful to practice on samples so as not to spoil high-quality workpieces and consumables.

Construction in stages: algorithm of actions, useful tips

This table shows the process of making beehives with your own hands. For example, we chose comparatively simple design"Lounger."

| Photo | Basic and auxiliary operations with comments |

|---|---|

| To reduce the cost of the project, purchase edged board 25 mm thick. It is cut to the required size, the burrs are removed with a plane. After grinding using sandpaper it turns out smooth surface no defects. |

| The blanks for the side walls are connected using wood glue. The ends are lubricated with it, after which the parts are pressed onto flat surface. For fixation, a vertical rib is installed on one side of the table. |

| On the other hand, it is fixed building level V in the right place(clamps). |

| You can put another blank on top to provide pressure from above and eliminate unevenness. |

| The end walls and bottom of the box are glued together in the same way. If irregularities are found on the large surfaces formed, they are removed using a grinding machine. |

| After checking the size match and eliminating minor defects, the box is assembled. The parts are secured with glue and self-tapping screws. |

| The accuracy of the angles is checked. |

| Next you will need wooden planks (10 x 10 mm). |

| They are used to make supports for frames. These elements are fixed using glue and nails. It should be noted that the author of the project specifically uses simple solutions. With the help of such instructions, you can quickly understand how to make a hive yourself without chamfering and other complex operations. |

| The check confirms the conformity of the dimensions of the parts. |

| A 40 x 20 mm strip is used to create a frame on each side of the drawer. |

| Tapholes are cut out in the side wall electric jigsaw(two at the bottom, one in the middle). During operation, they are opened as the bee colony grows. Attach the bottom. |

| The internal dimensions (76 width x 46 depth x 32 cm height) are enough to install 20 frames. |

| Install polystyrene foam (sheets 20 mm thick, density 25 kg per cubic meter). |

| A clapboard is mounted on top. |

| The multilayer construction is lightweight and has excellent insulating properties. This is better than using solid wood. |

| To make the lid, the boards are cut into 100 mm lengths. A box is made from these blanks. Install a rail at the bottom and check that the dimensions match. |

| The roof surface is created from lining. |

| Ventilation holes are cut out in the lid. Fixed with galvanized sheet metal for weather protection. |

| A stacked ceiling is made from boards. |

| At the final stage, the landing board is installed and the external surfaces are painted. |

| A special latch ensures the lid is secured during transportation. |

| A flexible band is used to secure the top in the raised position. |

Video: how to make high-quality frames for hives

The design, dimensions and other parameters of these products are determined not only by size free space. In some cases, a supporting frame of strings is not needed at all.

In this video, making a frame for a hive with your own hands from wooden blanks described in detail:

This material is easy to process and does not contain irritating or dangerous chemical compounds. But products made from it are damaged under the influence of temperature and humidity. They weigh a lot.

Such products cannot be made at home. Therefore, when choosing this option, you will have to study the assortment of stores.

Article

I'll tell you how you can decorate yours garden plot, namely let's talk about decorative hive.

Many people dream about their own home. A house, a garden, a lawn or meadow, there are flowers around, beehives, bees are buzzing over the flowers, birds are singing in the heights... An ideal rural picture.

In this idyll there is one very serious and difficult-to-reach factor - bees, they need to be looked after, and not everyone is given this. In addition, these insects cannot tolerate loud sounds. The lawn mower is often questionable, because the bees react far from unambiguously to this super-useful device. Bee stings cause allergies in many people. And if you have small children, then they and bees are two incompatible elements.

But you really want the perfect picture. And there is a way out! If you want to create a fabulously pastoral garden on your property, a beehive will come to your rescue, but without the bees.

It is not difficult to buy a decorative hive, both ordinary and stylized, since today there is no shortage of offers. Even find a hive that looks like a deck with thatched roof, is not particularly difficult. But if you want to show your creativity, then feel free to buy the most ordinary one and decorate it yourself.

As the first decorative option, the hive can be painted with bright paint, or with patterns, it’s all about your imagination, and the roof can be decorated with the same straw. But this option is not suitable for every site, although it will attractive center general composition.

The second option for decorating the hive is to glue small sticks around its perimeter. You can decorate the roof in the same way, and instead of the standard one you have wooden box a real beehive will come out, which seems to belong to a fairy-tale bear.

As soon as I have my own home, I will definitely install a decorative beehive in the garden! What do you think of this idea?

Live broadcast

Ingredients:

- salt;

- a little flour;

- seasonings for meat;

- 3 cloves of garlic;

- 2 eggs;

- refined oil.

Preparation:

There is one recipe for very tasty pork chops in eggs. Prepares in about an hour and a half.

Ingredients:

- 500 g pork tenderloin or loin;

- salt;

- a little flour;

- seasonings for meat;

- 3 cloves of garlic;

- 2 eggs;

- refined oil.

Preparation:

1. Cut the meat across the grain into circles or strips. Beat each piece well and rub with a mixture of salt and spices.

2. Break the eggs into a bowl and mix them with chopped garlic. Beat a little with a regular fork or whisk.

3. Pour flour into any container.

4. Heat the frying pan with oil well.

5. Take one chop. Dip it completely in flour, then dip it in the egg and garlic and immediately place it in the pan.

6. Fry over moderate heat for about 3 minutes on each side.

For those who are just learning, it will be interesting to learn how to make the face of a nylon toy.

The most important part in the work process is sewing the face of the future doll. It depends on him how good the finished craft will look. Naturally, this process must be approached as responsibly as possible.

What is needed: tights; synthetic winterizer; needle; thread. The most important part in the work process is sewing the face of the future doll

Work progress: Place the padding polyester into the prepared nylon. Pull it from the top and pin it with a pin. Roll up a small piece of padding polyester into a strip, making it a little thinner in the upper part, and tuck it in at the bottom. Place the formed nose in the center of the face being made. Form eye sockets, a little pressing down these areas with your fingers. Use pins to pin the places where the tightening will be done (the area of the bridge of the nose and the middle of the nose). Insert a needle with a thread folded in half where the first of the pins is secured and bring it out at the second mark. Go back and repeat the same steps, pass the thread through the loop that has formed. Pass each segment at least three times. Make nostrils in the area of the nose, initially marking these places with pins. Pull the lower edge of the workpiece at the base, pull the needle through the entire head and bring it out at the back of the head. Grab a little padding polyester with a thread to form lips. Sew additionally the bridge of the nose. Peel off the upper edge and add a little more padding polyester to the blank. Form the cheeks. Twist small rollers and form eyebrows from them. Pull out the ears. Bend the blank from above and stitch.

My favorite porridge is pea porridge, I recently found a recipe with meat. so delicious, definitely try it.

You will need:

dry peas - 2 cups;

water - 4 glasses;

onion - 2 large heads;

meat (pork) - 300 g;

Preparation

Boil the peas until tender over low heat.

Add salt and stir until pureed. If it is uneven, mash with a potato masher.

Cut the meat into slices.

Peel the onion and chop into half rings.

Fry the onion until tender, place the pork pieces on top, and cover with a lid.

Simmer over low heat, add spices and salt.

Place the roast on the puree and pour over the juice.

Preheat the oven to 180°, place the dish for 10 minutes.

In this article we suggest you make a craft from plastic bottles in the form of a beehive. For what? In this case, the waste is not sent to a landfill, but gets its second life as decorations for the home and garden. Plastic hives will add zest to your site. And original bees, made by yourself, will only complement such a house.

Materials

- Plastic bottle with a volume of 5 liters.

- Willow vine.

- Self-tapping screws.

- Scissors.

- Water-based paint.

Manufacturing

- A pot-bellied 5-liter bottle is covered with a frame; you can take a round hanger for this purpose. The structure is painted with water-based emulsion.

- After the paint has dried, you need to draw a notch in the middle.

- The frame is strengthened in two rows using willow vines. It is braided and then twisted around the circumference of the frame.

- Additionally, the roof is coated with unpainted glue.

- When the tail is formed, it is secured with several turns of twine.

Making bees

To make the composition unique and unique, you can make small decorative bees from plastic. You can make bees from Kinder Surprise capsules or from rubber gloves.

Materials

- Colored threads (two colors according to the color of bees, yellow and black).

- Contour for drawing veins (bronze and gold).

- Stencil in the form of wings.

- Scissors.

- Marker.

- Crochet hook.

- Pencil.

- Screwdriver.

Manufacturing

- Kinder surprise capsules are crocheted with alternating thread colors. The ends are neatly removed.

- Wings are cut out of a plastic bottle using a stencil. The veins should be drawn with a contour for greater realism.

- Using an awl, holes are made in the workpieces, and the wings are attached using bolts; they can be placed up and down.

- A small tail is made at the back, like a sting.

- Make a nose and eyes from beads and buttons.

- If you carefully draw the outline, the bees' wings will shine beautifully in the sun.

- The last step is to make a hole in the abdomen. An unnecessary knitting needle is inserted into it. All that remains is to attach the bee to the evidence.

Ready! Choose a place in your apiary where our bees will live. Now your yard will be cozy and joyful.

How else can you make bees that fit perfectly into a hive from a plastic bottle? Check it out with us!

Beekeeping is the most important industry agriculture different countries. The importance of beekeeping is determined not only by the most valuable products obtained from the apiary, but also by the role of honey bees in cross-pollination of plants and, as a result, increasing the yield of various crops.

The work of a beekeeper is hard work, requiring year-round attention and care from the beekeeper. First of all, high-quality beehives for bees are important, which must meet certain criteria. When choosing a house, the climatic and honey collection conditions of the region are taken into account, but there are a number of conditions that any of them must meet. So, what types are there, how to assemble beehives for bees with your own hands and how to properly place them in the apiary - you will find all this in our article.

General requirements for bee houses

Regardless of the design, each bee hive (a house where one or more families live) must meet fairly stringent conditions:

- dryness at any time of the year and with any amount of precipitation;

- high-quality thermal insulation, due to which a comfortable temperature is maintained inside in winter;

- good ventilation;

- space and potential for expansion as the family grows;

- relatively low mass designs;

- quality of finish - wooden house, painted and puttied, lasts at least 15 years.

A bee house of any design must also meet certain dimensions:

- between the wall and the side bars of the frames - at least 8 mm;

- between the central parts of nearby frames - 38 mm;

- frame thickness - 25 mm.

As practice shows, it is more convenient to use hives with magazine extensions in apiaries - they are lighter than nesting bodies.

Wooden parts that are used to make hives are prepared from aspen, linden or pine. Maximum humidity - 15%. There should be no cracks or fallen knots. If this is found, the holes are filled with putty.

Gaps in the houses are unacceptable - heat will escape through them and, accordingly, honey consumption will increase. To replace energy, the family will have to take in more food.

Since you need to build a hive accurately and correctly, this will allow you to combine their individual parts with each other. If we are talking about how to build a beehive for bees with your own hands, then the walls of the housings are assembled from 2-3 boards using the tongue-and-groove method and additionally glued with waterproof, non-toxic glue.

The outer side is treated with drying oil and painted in 2 layers of blue, yellow or white paint. The roof is made of stainless steel sheet.

Design (components) of beehives for a bee colony

Since making a beehive for bees yourself is quite troublesome, let’s decide on its main components:

- frame;

- store extensions;

- liner;

- ceiling boards;

- roof;

- arrival board;

- insert board (diaphragm);

- nesting/magazine frames.

The magazine frame is easier to remove from the honeycombs; it is easier to print the honeycombs in them and, accordingly, pump out honey.

- Frame

Externally, it is a box made of boards. Depending on the size and type of the hive, where there are more than 10 nesting frames or about 20 store frames, since they are smaller in size. The latter are secured by the shoulders on the rebate.

An entrance is made on the front side through which insects get inside. In some buildings there are 2 entrances - upper and lower, in others - one at a time, in still others (multi-hulls) there are also several, each of which serves for a specific family.

Knocked together from 3-4 boards or one flat one. Can be retractable or stationary. A protrusion is made so that the hinges for the flight can be screwed on.

Loops are used for fixation so that this board can be removed at any time. Remove it for the winter to prevent rodents from getting inside, or when moving for convenience. Bees need it for flight and landing.

- Magazine extension

A ready-made sample that is needed to artificially increase a bee colony. As a rule, standard frames are smaller than nested frames, but the same in width and height. If the evidence for bees is of a standard size, the store frames fully correspond to them.

Used to fix the ceiling insulation, resulting in a warm beehive. It can also be used to separate a family in order to form a layer with a fetal uterus.

- Ceiling

The ceiling strapping is a block as thick as the body. The bottom of the board is 20mm. Then the reflective insulation. Then - 20mm foam

A standard part, which is assembled from individual planks or made from solid wood. The temperature inside depends on the thickness and integrity.

- Roof

Beehives need protection from rain and snow, wind and debris. It can be different in shape - single- or multi-slope, sloping, acute-angled, etc.

For high-quality ventilation, ventilation holes or small slits are made in the sidewalls through which air will flow.

Used to reduce space inside the house for various purposes. So, during a sharp cold snap, you can put insulation behind such boards (polyurethane foam, moss, etc.). In a multi-body hive, the insert board is usually smaller than that of the bed and other samples.

The diaphragm shield is made from a board 45x32 cm, length - 47.2 cm, width - 2 cm. It is assembled from boards 1.4 cm thick, which are assembled by ¼.

For maximum tight fit, the ends are glued rubber seal, usually used to insulate entrance doors.

Required for the formation of honeycombs by workers. Consists of the following elements:

- top and bottom strips (hangers are made on the top for fixing on the fold);

- 2 dividing bars.

The standard size is 43.5x30 cm. In a lounger - 30x43.5 cm, in a multi-body, on the contrary, 43.5x30 cm.

The sizes of the frames differ depending on the type of hive:

- in a lounger - 30x43.5 cm;

- multi-body - 43.5x23 cm.

To assemble the frames, use standard nails 3 cm Ø 1.4 mm.

- Sectional frame

It is used to obtain honey in small quantities, for which it is divided into sections measuring 11x11 cm. Such sectional frames are made from wood chips 45x35x0.2 cm, after which they are placed in stores. On average, 380-400 grams of honey are removed from one section.

Types of cases

In total, the following types are distinguished:

- multi-hull;

- double-body for 24 frames;

- single-case with two stores;

- sun lounger for 20 frames;

- lounger with 16 nesting frames;

- bed for 16 magazine frames.

In this article we will tell you how to make beehives for 20 frames and multi-frame hives. These are the most popular types that can be found in most apiaries in Russia. Let us immediately note that the sizes of the hives are standard.

Multi-body (TP No. 808 5 1)

It consists of 4 buildings, each of which can accommodate 10 nesting frames measuring 43.5x23 cm. This is a prototype of a stationary and nomadic modern beehive.

What you will need for construction:

- boards - 0.3 cubic meters;

- galvanized - 2 kg;

- investment steel - 0.2 kg;

- galvanized mesh - 0.2 sq.m.;

- nails - 1.5 kg;

- galvanized nails - 0.1 kg;

- screws - 10-12 pcs.;

- loops for the arrival board - 10 pcs.;

- wooden insert for the taphole - 4 pcs.;

- holder for ventilation frames - 2 pcs.;

- drying oil - 0.5 l;

- whitewash - 0.3 l;

- paints - 0.3 l.

- The box is assembled from boards 3.5 cm thick. The internal dimensions of the house are 45x37.5x25 cm. The walls can be made of solid wood or assembled from several boards, but must be glued together with non-toxic waterproof glue to avoid cracks and holes.

For nomadic houses, folds of 1.8 x 0.5 cm are hollowed out on the walls at the top and bottom in order to insert one into the other during transportation.

- Folds are hollowed out inside for attaching frames. Their dimensions are 1.1x2 cm.

- On the front part, at a height of 12.5 cm, a hole Ø 2.5 cm is cut out - this is the future entrance. A bushing is immediately prepared for it, which will fit tightly, but in such a way that it can be removed without significant effort.

- The length of the sides is 49.6 cm, the height is 25 cm, the length of the walls is 44.5 cm, the height is 25 cm.

To make it convenient to move the structures from place to place, you can make a recess on the top part as a hand holder.

- The bottom is removable. This is a sloping shield at an angle of 23°, which goes from the back to the front. It is usually made from 2-3 boards 3.5 cm thick. Be sure to make edging at the ends, and protrusions are made on the side of the landing board, where the hinges are then screwed.

- The lower part of the bottom is sheathed with 5x3.5 cm boards, which will prevent the bottom from rotting and the hive coming into contact with the ground.

- The ceiling is knocked together from 5 boards, which are fixed across the top with planks. Ceiling dimensions 496x40x1 cm.

- Dimensions of the roof liner outside 52x44.5 cm, from the inside - 45x37.5 cm.

- The roof is made completely flat so that the hives can be assembled during transportation. They are tied with 10.5 x 2.4 cm boards, joined using the tongue-and-groove method and additionally fixed with non-toxic waterproof glue.

- The dimensions of the frames are 43.5x23 cm with stationary slats.

- The parameters of the top bar are 47x2.5x2 cm.

- Side bar - 22x1 cm.

- Bottom bar 41.5x2x1 cm.

- The ventilation frame is used to transport insects or to isolate them during the period of house treatment and prevention.

- side bar length - 47 cm;

- walls - 37.5 cm;

- thickness - 2 cm.

They are attached to the vent frame metal mesh with holes up to 3 mm.

All wooden parts smoothly planed and protected with fine sandpaper. The dimensions of the hives are strictly observed.

As the experience of beekeepers shows, such a construction is not very complicated and at the same time, it is the most convenient design. First, it helps strengthen the family and increase productivity. Secondly, it allows you to combine cases with each other. Thirdly, such convenient boxes are easier to transport and carry, including in stationary apiaries to and from the winter hut.

VIDEO: How to make a multi-body hive with your own hands

How to make a beehive with 20 frames

Drawings of these varieties are made according to standard project 179 60. The convenience lies in the fact that you can keep 2 families at once - provided that the housing is divided into two independent compartments and each is equipped with its own entrance.

The maximum benefit can be seen in winter - 2 families, although separated by a bar, spend in total less energy and feed. In such evidence it is always warmer than in multi-hulled ones, even for several bee colonies.

What you will need:

- boards - 0.2 cubic meters;

- galvanized sheet - 3 kg;

- galvanized mesh with a mesh size of 3 mm - 015 sq.m;

- round washers - 0.02 kg;

- screws - 0.2 kg;

- nails - 0.25 kg;

- galvanized roofing nails - 0.1 kg;

- staples - 2 pcs.;

- metal clamps - 2 pcs.;

- inserts for the arrival board - 4 pcs.;

- drying oil - 0.5 l;

- whitewash - 0.3 l;

- paints - 0.3 l.

- crushed chalk - 0.4 kg.

The main difference between the Ukrainian model and the Belarusian and Russian is the insulation of the front and rear walls.

- The body is knocked together from boards. The dimensions of the finished box from the outside are 83x44x60 cm. The thickness of the outer walls is 1.5 cm, the inner ones are 2.5 cm. The length of the walls is 83 cm.

- The sidewalls are assembled from 5 planks, a shell-shaped hole is made on top for the pressure board, and at the bottom for inserting the bottom. Wall size 42x3.5 cm.

- Make 2 lower tapholes 20x1.2 cm - one on the front part, the other on the side. The top two are also made, but with different dimensions - 10x1.2 cm. Be sure to maintain an equal distance from the bottom of 34 cm, and from the edge - 16 cm.

- The landing board is attached to the bottom with loops.

- The bottom is made from 3 planks. Be sure to provide a clamping bar with which to secure the frames during transportation of the apiary.

- The frames are made high, but narrower than the standard - 30x43.5 cm.

VIDEO: The most detailed description sun lounger for 20 frames

It is important to understand not only how to make hives for future families. But also how to properly place them in the apiary, so as not to lose them in the first year.

The ideal place for an apiary is moderately sunny, moderately shaded. Honey plants nearby

The location is chosen depending on the conditions and terrain. If you put them on open area, then at noon the workers stop working, everyone leaves the house and hides in the shade under the landing board or even crawls under it.

For hives located in unshaded areas, the swarming rate is more than 70%. And productivity is 45% lower.

The direct consequences are very severe sun rays during transportation - the next shock on a road bump leads to the fact that the softened, newly built honeycombs break off. This leads to the death of not only the workers, but also the brood, and in some cases the queen may also die.

There are certain requirements for setting up hives in an apiary:

- The hives are placed “facing” south. This will provide excellent lighting during daylight hours, and the back wall facing north will protect the family from strong gusts of wind.

- It is advisable to grow behind the houses large shrubs or trees to serve as an additional barrier to the winds.

- Even before you make a hive for bees yourself, make sure that there is a source of water in the place where they will stand. But even if it is not there, the problem can be solved through collective or individual drinkers.

There must be a source of water nearby - it is no less important for a bee than for a person

- Do not allow direct contact sunlight on the roof and the house itself, but you shouldn’t shade it too much. This arrangement will limit ventilation and artificially increase the length of the day for bees - they will fly out earlier and return later. This will accelerate their wear and lead to earlier death.

- The location for the apiary is chosen so that honey plants grow nearby. This will enable workers to prepare food faster. The maximum distance should not exceed 1.8-2 km.

- It is necessary to make hives in such a way that it is possible to insulate them for the winter using moss or polyurethane foam.

When insulating, avoid direct contact of insects with polyurethane foam. To do this, it is lined with canvas.

- All the grass is pulled out in front of houses that have already been exhibited and those that are just being exhibited - the beekeeper should have the opportunity to control the type and quality of garbage thrown out daily by minke whales. On the one hand, the quality of the garbage will show the condition of the family. On the other hand, the absence of grass will make it possible to notice the prolapsed uterus in time - this happens quite often.

- Attach planks to the landing boards - this will allow loaded bees to get into the house faster. This device is especially important during windy times.

So, we told you how to make a hive for bees yourself, what materials are needed for this and how to properly install houses in the apiary. If you have any questions or want to clarify some nuances, ask questions in the comments - our specialists will be happy to help you!

VIDEO: Moving an apiary, fastening hives, transporting bees

After you have decided to become a beekeeper and have bought a couple of colonies, the time comes for you to need new hives. Families grow and swarm, and they need to be moved to new houses. You can, of course, buy ready-made ones, but buying used ones is dangerous. It is unknown what diseases can be purchased with them, and the new prices are steep. There is only one thing left - to make beehives for bees with your own hands according to the drawings. If you know all the manufacturing rules, then it’s not difficult at all.

In this article we will just talk about making beehives with your own hands, correct sizes and drawings for them. Let's find out what a beehive is and how to make it.

In ancient times, beekeepers extracted honey from hollow trees, then they began to hollow out logs for bees. With the development of beekeeping, people began to make evidence for bees with their own hands. different designs, and the material used on them is different.

Tree

A classic option for making bee hives. In such houses, bees feel in natural conditions, close to natural ones. The best type of wood for manufacturing is cedar, although linden and aspen are also possible. Such hives breathe better, smell nice and are dry.

Hives made of aspen and linden require additional insulation in winter. And these are expensive materials.

Some beekeepers make their own hives from cheaper materials. This is pine, spruce, fir. But the bees are not comfortable in such evidence. They collect moisture and resins, especially in new ones.. Pine smell. There is only one good thing about them: they are warm and require minimal insulation for the winter.

Plywood

Durable and environmentally friendly material. A house made from it must be painted and insulated from the inside with polystyrene foam, then it will be dry and warm. But plywood is afraid of moisture and requires constant and proper care.

Expanded polystyrene

Modern material used by beekeepers to make hives. It has a low cost and does not require additional insulation in winter time.

The disadvantage of this material is fragility and brittleness. If you choose poor quality, the honey may deteriorate.

Foam plastic

The most economical option. It is possible to use packaging from household appliances. The advantage of this material is its lightness even with filled frames. Excellent thermal insulation. The disadvantage of this material is its fragility and permanent coloring so that it does not crumble from exposure to sunlight.

Polyurethane

Excellent thermal insulation properties. Does not rot, does not decompose. Fungus and bacteria do not develop in it. It does not allow moisture to pass through and it does not accumulate inside. Bees, mice and birds do not like to chew on it.

A small downside is that it is flammable and requires ventilation because it does not allow air to pass through.

After carefully studying the characteristics of the material, you can begin building the hive. Let's consider options for building wooden and foam houses.

Types and designs of hives

Bee houses are divided according to their design:

- collapsible;

- non-separable.

Almost no one uses the latter because they are difficult to care for.. All beekeepers use frame hives, where the number of frames can vary. A DIY beehive with 24 frames is popular. However, there are options for 16 and 20 frames.

In turn, frame hives are divided into:

- horizontal;

- vertical.

The horizontal or “bed” consists of one body. The expansion goes to the sides. It is easy to work with such evidence and change the number of frames, but they have a drawback - they are bulky and heavy.

Vertical ones consist of several buildings. This form is lightweight and mobile.

Both forms use multiple sections. They are separated by partitions, which allows you to change volumes in any direction.

Popular designs

Dadanovsky

Used in almost all apiaries. Made from wood (cedar, spruce, pine, linden, aspen). It is simple and spacious. Consists of 12 frames and can be supplemented with shops or cases as the family grows. In winter, bees are kept in the nesting compartment. As the weather gets warmer and the family grows, they are added to the buildings.

Alpine

Multi-body hive. The creator is French beekeeper Roger Delon. Made according to the hollow principle. That is, the natural living conditions of bees have been created and taken into account.

Compact design is convenient for tight spaces. It has no partitions or ventilation holes. Air naturally enters through the tap hole.

Ruta

This DIY bee house designed for keeping bees in the southern regions, because due to constant rearrangements of the buildings, hypothermia occurs in the house. Consists of 6 cases of 10 frames each.

Cassette

Due to the increase in the incidence of bees, cassette hives have become popular among beekeepers. Such evidence have thin partitions, so bees create a microclimate on their own.

They are made only from wood and impregnated with wax, so the bees in them are less susceptible to diseases.

Ukrainian lounger

This hive design is the largest in size suitable for beginners. They are easy to maintain. Easy to build, which will allow you to master beekeeping skills. Usually such hives have 20 frames. The sides of the house are insulated, so the bees winter well in them.

There are many designs of evidence, but let us dwell in more detail on the classic one, a lounger with different quantities frames and multi-body non-rebated. IN in this case There are beehives with 16, 20 and 24 frames.

How to build a classic hive step by step

Due to the ease of manufacture, classic version considered the Dadanovsky hive.

To make hives, it is better to use natural materials.

The classic design for hive production consists of:

- One or more buildings.

- One or two stores.

- Liner.

- The bottom of the hive.

- Ceiling.

- Roofs.

- Framework.

- Feeders.

- Insert board.

Bee house instructions with drawings

Now let's talk about how to make a beehive with your own hands step by step. The sizes of a bee hive can be very different, but we will focus on one option. To do this you will need:

A 15 mm thick board is required for the lid and liner. Collect and cover with tin to prevent water from entering. Paint it. Make ventilation holes with a diameter of 1.4 cm.

- back and front shield (cm): width 53, height 32, thickness 4.

- side shield (cm): width 48, height 32, thickness 4.

- internal (cm): width 45, height 45, thickness 32.

In order to place the frames in the body, folds need to be made.

Dimensions 1.1 * 2 cm.

If there is a multi-body bee hive, then the dimensions will be different: 1 * 1.4 cm.

The frame located in the nest is 43.5 * 30 cm;

Magazine frame - 43.5 * 14.5 cm;

The distance from the walls of the case to the side strips is 0.07 cm;

The space for the frame is 2.5 cm;

The width of the side of the frame is 3.7 cm.

Hive-bed for 16, 20 and 24 frames: drawings and dimensions

Hive-bed for 16, 20 and 24 frames

Hive-bed for 16, 20 and 24 frames What tools and materials will be needed?

- Wood, plywood, foam.

- Rulers or tape measures.

- Squares;

- Hacksaws.

- Hammers.

- Drill, drill, self-tapping screws.

- Chisels.

- Glue.

- Carrying handles.

- Galvanized sheet for the roof.

- Frames in the amount of 24 pieces.

Hive dimensions:

- frames 30 * 43.5 cm;

- body (cm): length 87, width 56.5, height 63.5;

- roof length (cm): outside 93.5, inside 81;

- bottom thickness 3.5 cm;

- lower entrance - 1.2 * 14 cm;

- the upper tap hole is 2.5 cm in diameter.

Instructions for making a hive for 24 frames

- Cut out parts from the prepared material according to the drawings.

Observe the dimensions exactly so that the construction of the bee trap with your own hands is even and without large gaps.

Instructions for making a hive-lounger

Instructions for making a hive-lounger - Assemble the bottom. Connect the two slats and the deck using primer and nails.

- Connect side walls and attach to the bottom. Make a protrusion beyond the bars of 2 cm.

- Make grooves for frames on the front and back walls. Size 1.8 * 1.1 cm.

- Cut holes from below.

- Attach the valve and the landing board.

- Make a roof. Fasten the boards with nails into tenons.

- Attach opening hinges to the roof.

- Cover the roof with tin.

- On back side make a ventilation hole 20 * 0.03 cm on the roof.

- On the front wall drill a hole with a diameter of 2.5 cm.

- Cover them with a net.

- The legs are strong to the bottom.

- Dry and paint.

- Attach handles to make it convenient when carrying.

Should be painted white. Bees remember this color better. White repels sun rays.

How to make an evidence bed for 20 and 16 frames

It is made according to the same principle with a difference in size.

Multi-body beehive: dimensions and drawings.

Over the years, this hive has not lost its popularity in use. Convenient design allows them to be used everywhere. And it’s easy to make.

In order to properly build a hive, you need to know what the structure consists of:

- Lid.

- Roof liner or ceiling.

- Shops.

- Cases.

- Stand.

- Framework.

- Dividing grid.

The body looks like a box. Its size from the inside (cm): width 37.5; length 45; height 24.

It includes 10 - 12 frames measuring 43.5 * 23 cm.

These sizes are more suitable for regions with warm climates, and for the Russian climate the width is made half a centimeter larger.

Reducing the size leads to inconvenience in working with frames. It is impossible to get them out when they are heavily polished or swollen from moisture. Therefore, some increase the width of the case to 38 cm.

To make cases, you need to take carefully dried boards. They should dry out within a year. When cutting out parts, the boards should have a small margin (3-5 mm). The stock is left for further fitting of parts. For trimming, it is recommended to leave an overlap of 1 cm.

Make folds on the front and back parts of the body to place frames on them. Sizes 1.1 and 1.7 cm. This depth allows you to freely place the upper body.

Handles or small recesses need to be attached to the side walls.

A 25 mm hole is drilled from the end of the hive under the roof to ventilate the house.

Boxes with frames are tightly connected to each other. In this case, folds are not used. This constructive solution more convenient to use and simpler to build.

In cases using folds, during transportation or movement, bees most often get stuck in the lower part and hide in the folded recesses, subsequently dying. Most often, the queen dies in them and beekeepers abandoned such hives in favor of a non-rebated design.

To make the roof, a 2 cm thick die is taken. A shield is knocked together from it, which is covered with galvanized sheet.

It is better to make the bottom removable, double-sided.

- three bars 57*6.5*3.5 cm - side;

- one 44.5*6.5*3. cm is installed at the rear.

Make grooves in them. Width 3.5 and depth 1 cm. Assemble a U-shaped structure. The grooves are designed for installing a floor slab.

It is necessary to provide a front projection of 50 mm. It serves as an arrival board.

The roof liner (ceiling) is a solid shield assembled from dies, measuring 52 * 44 cm. Around it is a rim made of slats. They are 3.5 cm wide and 1.5 cm thick. There is a hole in the center. It is needed for ventilation between the buildings or a feeder is placed on it.

The liner is placed on the body with the smooth side without the rim, which allows the bees to move freely. It can also serve as a dividing grid; in this case, a mesh is stuffed over the hole.

Stand. It is made from bars according to the size of the bottom. A wide die is nailed into the front part at an angle of 45°. This will be the arrival board.

A recess measuring 2.5*9 cm is cut into the side bars. They are designed for convenience when you need to lift the hive or secure it when moving.

To increase the service life of the bars, impregnate them with liquid bitumen. Dissolve it with gasoline. This procedure will make the wood waterproof.

Dimensions of the dividing grid. Designed to isolate the temporary isolation of the uterus. To separate the body with brood from the honey ones.

The size of the grille must match the size of the inner housing. It is placed on bars. Made from wire mesh.

Frame sizes. Case and magazine frames can also be made with your own hands. They must correspond to the drawings.

Drawings of multi-body hives.

Frames for the hive: dimensions and description of how to make it yourself

Frames are an important part of hives and the main work is done with them. From constant use they become unusable and need to be added. Therefore, the beekeeper should always have a large supply. To save money, it is better to make them yourself than to constantly purchase them.

To make frames we will use the following tools:

- hammer;

- pliers;

- awl;

- shoe nails;

- a skein of thin wire.

For production, use natural materials. It is better if these are boards that have been dried for a year. To make a frame you need to know what parts it consists of:

Top bar.

Grooved or uniform.

Bottom bar.

Regular, grooved or through-gap.

Side bars.

They have holes for pulling the wire under the foundation.

Frame sizes depend on the design of your hive. Standard sizes are considered:

- the width of the top and side boards is 2.5 cm;

- the height of the top block is 2 cm;

- bottom width 1.5 - 2.5 cm;

- height 1 cm;

- external dimensions vary depending on the design of the hive, but usually 43.5 * 30 cm.

After we have chosen the material and decided on the dimensions, we proceed to the actual production of the frame.

- Cut out parts from dry boards according to the dimensions of the drawing.

- Using shoe nails, connect all the parts.

- Drill 4 holes and two double holes on the side strips for attaching the wire. The distances between the holes must be equal.

- Pull the wire. Start from the top hole and snake it through. Make sure that the wire does not intersect anywhere. Fasten it securely so that the heavy honeycomb does not accidentally break off. As a result, you should have 4 lines.

The foundation is fixed onto the frames prepared in this way.

Now you know how to make bee hives yourself with your own hands with drawings. Using the drawings and dimensions, you can easily build it yourself, thereby saving your budget and providing it to the bees comfortable conditions accommodation.