Lubricant for molds in the manufacture of rubber tiles. Useful information

To lubricate or not - that is the question.

For many producers of small-piece concrete, including paving slabs, the issue of lubrication of molds for better separation finished products and reducing the number of rejects during stripping. As you know, release agents are always used in the production of large reinforced concrete products. But often, in the production of such products decorative properties are not as important as in the production of paving and, especially, facing tiles. In turn, it should be noted that careless attitude to the release agent and the process of its application can lead to loss of presentation and damage to decorative products. How to do it - you ask. Let's try to understand the process of lubricating molds.

So, lubricant is used to prevent concrete from sticking and form contamination - this is understandable. The lubrication process can be done manually - with a brush. Or you can spray a release agent, for example, with a spray gun or spray gun. The molds are lubricated immediately before the concrete is formed, each mold is lubricated separately.

Experience shows that it can be improved production process and without lubrication, but this entails an increased load on the mold and more frequent washing. For example, the Noria company has been producing paving stones using the injection molding method since 2001. During its entire existence, the mold lubrication process was introduced for only one season. Various lubricants of domestic and imported production were used. The lubricant was applied manually and later with a spray gun. But the result did not suit the production manager - with an increase in production volumes of paving stones (Antique No. 2, 52 pcs./m2), the lubrication operators could not cope with the process. Imagine, production reaches 130 - 150 m2 per shift, and if there are 52 pieces in 1 m2, then the lubrication section must process more than 6000 pieces. forms per shift. Errors by the lubrication operator lead to an increase in scrap, plus the cost of labor and materials increases the cost. As a result, this enterprise has improved the mold washing area and the concrete composition (now the composition is strictly controlled by the w/c ratio - the “harder” the solution, the less it sticks to the formwork). And it has successfully existed without lubrication for more than 10 years.

Today there are many domestic and imported lubricants on the market. Let's consider several options:

Emulsol.

Emulsol is a modern water-based lubricant, easy to use and inexpensive. It consists of biodegradable substances, which eliminates the adhesion of concrete to the surface of the form. Lubricants of this type are made from environmentally friendly substances; they do not require special safety measures when working with them. When applied evenly thin layer lubricants significantly reduce the adhesion between the concrete and the mold, the porosity of the surface of the products, and do not leave stains, which allows you to obtain products with a smooth and clean surface without subsequent finishing or grouting.

Emulsol prepared in a ratio of 1/3 to 1/5 with water. It is applied to each form with a brush or by spraying, carefully coating the corners and edges of the front surface of the form. In conditions high level The pH in water can be added to the solution soda ash(2% of mass fraction emulsol).

It is worth stirring the solution thoroughly, although the lubricant dissolves well in water. Emulsol can be used not only for plastic molds, but also for metal ones. It perfectly protects metal from corrosion. It is not recommended to prepare the emulsion for more than one shift.

FREM SLAE - III

New generation anti-adhesive lubricant for molds and formworks, based on animal fats and surfactants.

When applied to cold and hot molds and during heat treatment, it does not decompose and does not release into the air. production premises products with a strong odor or that cause harmful effects on people and the environment.

Scope of application:

- used in the production of prefabricated and monolithic concrete and reinforced concrete products and structures

- effective both for molding products without heating and using heat and humidity treatment (HMT).

The main purpose of lubricants for metal molds is:

- facilitating the separation of concrete from the mold or formwork material

- security good quality the outer surface of products by reducing the number of defects - tears, peeling, etc.

- protection of metal forms from corrosion

Advantages:

- absence of oil stains on the surface of products

- reducing costs for final finishing concrete structures

- does not leave marks, does not change the color and texture of the surface

The lubricant is a concentrate that should be diluted with water in a ratio of 1 part lubricant to 3-6 parts water. In this case, no water preparation is required.

Apply the lubricant to a dry surface free of concrete residues. Applying excess lubricant leads to a decrease in the quality of the concrete surface, waste of material and unnecessary increase in cost.

Lubricant consumption when applied to molds with a brush or brush is from 30 to 50 g/m2.

Concentrate 1:10 with water

- Packing: 5 l

Special stripping lubricant for tiles “Lerossin”- an unsurpassed anti-adhesive drug based on animal fats. Water-soluble light gray emulsion - has no pronounced odor, is not flammable, and does not contain harmful or aggressive substances. Due to its high capillarity, Lerosin is able to form a thin layer on the surface of the mold, facilitating easy separation of concrete. Does not affect the color of products, helps reduce the porosity of the resulting surface. Low cost and low specific consumption make Lerosine a lubricant optimal choice in the production of paving slabs.

Buy plasticizers for concrete inexpensivelyYou can visit our online store by placing an order by phone or through the online shopping cart.

Lubricant for plastic forms of paving slabs Concentrate 1:10 with water Packaging: 5 l Special stripping lubricant for tiles “Lerossin” - an unsurpassed anti-adhesive drug based on animal fats. Water-soluble light gray emulsion - has no pronounced odor, is not flammable, and does not contain harmful or aggressive substances. Due to its high capillarity, Lerosin is able to form a thin layer on the surface of the mold, facilitating easy separation of concrete. Does not affect the color of products, helps reduce the porosity of the resulting surface. Low cost and low specific consumption make Lerosin lubricant the optimal choice for the manufacture of paving slabs. You can buy plasticizers for concrete inexpensively in our online store by placing an order by phone or through an online shopping cart. Packing of material (kg) 5 Packaging Canister Type Lubricant for molds Condition Liquid Application supplements For... more

Lubricant for paving slab molds does not work last role in the production of tile products. Certainly, concrete mortar, dyes, plasticizers and the right technology directly determine the quality of future tile products. Good lubrication makes it easier to remove products from molds and preserve (or even improve) them appearance. Moreover, it prevents the appearance of pores on front side paving slabs and paving stones.

For high-quality styling tiles, it is necessary to carefully prepare the molds for its manufacture.

Before pouring concrete into molds, they must be thoroughly cleaned and lubricated. By the way, they are made from various materials and there are metal, plastic, polyurethane, wood (formwork).

High-quality lubricant does not affect the shape, does not change the color of the cast tile and does not have a destructive effect on it.

The choice is quite diverse: all kinds of emulsions, powder and soap solutions, mineral oil concentrates, etc.

Variety of mold release agents

For small volume production tile coverings You can go to your nearest service station and purchase lubricant for a nominal price or for free. For large volumes of tiles and paving stones, special domestic and foreign lubricants are used. We list the most popular and frequently used in the manufacture of paving slabs and paving stones:

At home you can make a lubricant based on motor oil.

- KSF-1. Available in the form of a homogeneous paste, it is characterized by low consumption, ease of application, provides an even, smooth surface and does not leave colored spots on it. The lubricant is non-toxic, dissolves well in cold and warm water. Used as an emulsol - 9-10% aqueous solution. You can lubricate the molds with any means at hand. Used for plastic, metal forms and formwork.

- Kristal, based on light mineral oils, is an environmentally friendly product, has excellent anti-corrosion properties, and is used for metal and wooden forms. Apply with a brush or spray.

- Nometal also protects metal molds from corrosion, cracks and pores.

- Agate, used for any shape, is a very economical lubricant, allowing 1 liter to cover 35 square meters. m. surface, has many positive reviews.

- Anti-adhesive concentrate Tiprom 90 based on silicones, which has water-repellent properties, is usually used for the production of large slabs in metal and polymer forms. Does not respond to temperature.

- Emulsol, made on a mineral basis, is often used in construction to lubricate formwork. Consists of biodegradable substances. It is applied with a sponge or spray, is quite affordable and is very suitable for the manufacture of paving slabs, without requiring subsequent grouting or finishing.

Many lubricants are available in the form of concentrates. Concentrates differ in that you can get more of the finished product from them. To do this, add them to water and stir for 5 minutes.

How is lubricant applied and is it possible to save money on it?

For easy removal of paving stones, the mold must be lubricated.

Apply a thin layer of lubricant to each mold with a brush or spray, depending on the selected lubricant. Before application, as already mentioned, you need to thoroughly clean the molds of debris and dirt. They need to be lubricated immediately before pouring concrete. No special clothing is required to apply the lubricant. It is enough to wear gloves to protect your hands from contamination. If the spraying method is chosen, it is better to wear a respirator.

When applying with a brush, you need to ensure that all corners are treated and the bristles do not remain in shape. Any little thing can ruin the appearance of the tiles.

It should be noted that lubricant not only improves the process of removing tiles, but also significantly extends the service life of the molds, reducing the load on them.

Now here is a recipe for a simple and cheap DIY lubricant. Take 50 g of motor oil and dilute it in 1.5 liters of water. Shake it up. This needs to be done for quite a long time. We test on the product. You can experiment with proportions. A greasy lubricant can create pits in the tiles or oil stains on the surface, while a weak lubricant will worsen the removal process.

Some tilers use it to rinse molds. brine. Hydrochloric acid diluted with water, and forms are lowered into a 7-10% solution. Then they don't lubricate.

Some people use soapy water. It is prepared from ordinary soap or dishwashing liquid. Naturally, the savings are obvious, and the slipping of the tiles out of the molds will also please you, but they remain very dirty after it.

To summarize, let us once again outline the three main functions of a release agent:

- easier removal of products:

- reducing labor costs for cleaning molds and formwork;

- maintaining the quality of products and their appearance due to the fact that the concrete does not stick to the form and the tiles do not have to be “torn off”.

By saving on lubricant, you can lose much more on discarding. Even when producing tiles for their own needs, everyone wants them to be beautiful, strong and durable.

To give your yard or garden a neat and finished look, you can fill it with concrete, but it will look much more aesthetically pleasing if you line it with tiles or paving stones. You can buy ready-made material, but there is also the option of making it yourself in special forms. This requires a concrete solution and a special lubricant, the purpose and properties of which will be discussed below.

Benefits of using lubricants

Tiles are small concrete pieces that are used to lay the covering on paths. It comes in different shapes and colors and is made from different materials. But for the production of each of them, a lubricant is used. Concrete and various additives will play a role main role as tiles, but mold lubrication is also important. It is used to remove tiles to preserve their appearance. In addition, it reduces the likelihood of pore formation on outside tiles

Before pouring the concrete solution into the mold, it must be cleaned of dust and debris and lubricated. Such forms are made from metal, plastic, polyurethane or wood. If the lubricant is of good quality, it will not affect the tile in any way, neither the shape nor the color. Such lubricants are produced in the form of emulsions, powder and soap solutions, oil concentrates, etc. The sample is coated with a thin layer of lubricant, and no special clothing is needed.

Species

Lubricants are primarily classified into:

- made from improvised materials;

- specialized.

What they have in common is that they help remove tiles.

Made from improvised materials

Types and their main characteristics:

- saline solution - diluted with water, low price, possibly causing stains that are difficult to clean;

- motor oil - it is applied with a sponge, it is cheap, the sample is easy to wash, it can affect the color of the tile;

- Soap solution is liquid soap, it is used to lubricate the walls; it is not easy to wash samples.

Lubricants from improvised means are especially relevant when producing small quantities of paving stones, when purchasing a special liquid is impractical. In such cases, you can go to a transport service station and buy a small amount of the product.

Specialized

If you need to lubricate many molds to produce large batches of tiles, you will need to purchase special remedy. They come in different brands, so finding one won't be a problem.

If you need to lubricate many molds to produce large batches of tiles, you will need to purchase special remedy. They come in different brands, so finding one won't be a problem.

- Kristal - the basis of such a lubricant are light mineral oils. They are environmentally friendly and have anti-corrosion properties. The material is used for samples made of metal or wood. Application is possible either with a brush or with a spray;

- KSF-1. It has the form of a homogeneous paste. It is economical to use and easy to apply. With its help, it turns out smooth and smooth surface. The material is environmentally friendly, washes off with water. Easy to apply to plastic, metal and wood forms;

- Tiprom 90 (concentrated anti-adhesion liquid). The basis of this solution is silicones, which tend to repel water. More often used for lubricating molds (made of metal or polymer) in the manufacture of large slabs. Temperature resistant;

- Nometal. Used to protect metal forms from corrosion and cracks;

- Emulsol – made on the basis of mineral substances. Used for formwork. Apply with a sponge or spray. It's inexpensive. Used in

Any garden or vegetable garden needs beauty and care. The most best choice, at the same time, there will be laying of tiles on the paths. It will help improve the appearance of the dacha, creating an atmosphere of prosperity and neatness. You can purchase tiles in a store or create your own. All that is needed to accomplish the last point is a little skill, the presence necessary materials and properly selected lubricant. Lubrication is necessary to create the shape of paving slabs. It can be self-made or specialized. The choice of what to lubricate with often depends on the level of production, as well as the structure of the formwork.

Varieties of paving slab shapes

Tiles are small pieces of concrete that have different shapes and laid on the path.

There are several types of structure:

- In the shape of a rectangle.

- Free

- Universal.

- In the form of a model.

- Castle.

- Ecological.

Among other things, tiles can be cast or pressed. The second option assumes the presence special devices, as well as skills and abilities. Doing it yourself is a rather difficult and time-consuming process. It is much easier to make cast tiles. To do this, you just need a little patience, strength and skill.

Materials for pouring: plastic, concrete

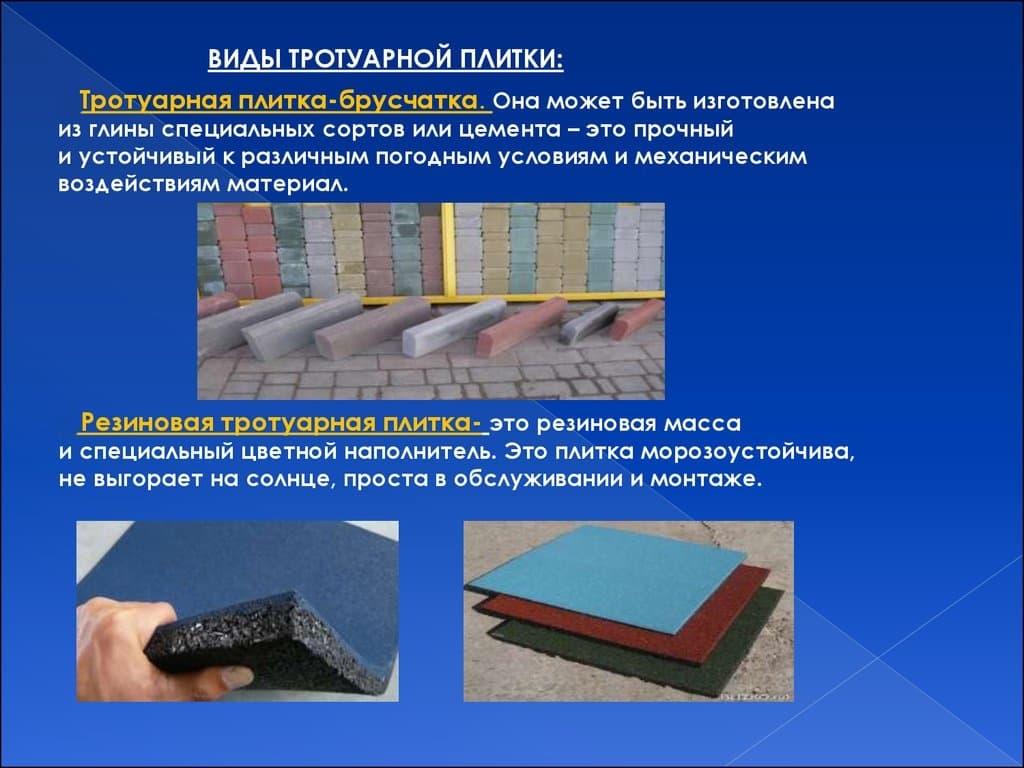

There are types of tiles based on the content of materials:

- Made of cement and sand.

- Made from baked clay.

- Made of rubber.

- Made of plastic.

- Made from granite.

Cement tiles have a number of positive properties: they are durable, do not fade even after a long period of use, and do not allow moisture to pass through.

Clay paving stones come in a variety of colors and have anti-slip properties.

The rubber pieces are made from polyurethane, a material widely used in the soles of shoes. This tile is characterized by softness and slight surface roughness.