Staircase to the second floor - modern, safe and attractive design. Do-it-yourself stairs to the second floor How to properly position the stairs to the second floor

There are some design rules. Very often, construction work is divided into several stages. Sometimes the house itself is erected by some workers, and completely different contractors are engaged in interior decoration. Such, at first glance, savings, only complicates the work.

Because then the stairs have to be designed, adapting to the already prepared conditions. It's not easy. Even if a person builds his own house, from beginning to end, he needs to know the rules that we will now discuss. Everything seems to be a simple task. Our safe moving structure can be said to be one of the toughest challenges.

Capitalism of the premises, as well as the degree of its fire resistance, these aspects become key in choosing materials for the stairs. The shape depends on the area that is allocated for the staircase. Also, the shape is influenced by how high the ceiling is, and what architectural style the builders of the house as a whole adhered to.

There is a very convenient, and to the maximum safe option of lifting, and reverse movement on the stairs. This option is considered a gentle staircase with one march and fifteen steps. So, let's start designing.

Most often, these types of structures are designed in the construction of country houses. But, sometimes, limited space forces you to look for alternative areas in the house to create spiral staircases. This is a practical option due to the fact that winders fit easily into any type of project.

Much more space is stolen by structures of stairs with two flights. They take up more space. Than a screw design, but less space than a simple flat analogy. The project may involve both winder steps and the area between marches. If the staircase will be completely manufactured and installed independently, then the advice is to pay attention to such material as wood.

It is very easy to process. In addition, small errors are quickly corrected without costly additional costs. The components of the structure can be made not on the spot, like concrete stairs, but separately. Metal stairs are also assembled separately. The drawing is calculated for any type of stairs. This also applies to spiral, gentle, semicircular, and with two marches, stairs.

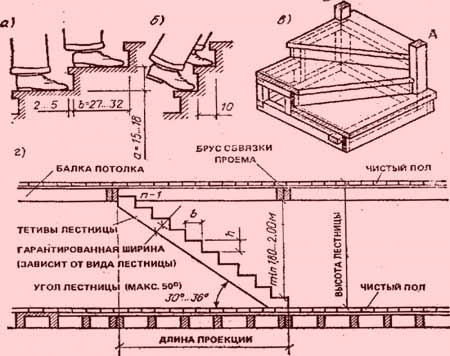

What parameters should be taken into account when creating a staircase project? First of all, you need to start with measurements. You need to measure the area, and put the dimensions on the plan. Next, you need to measure the openings. You also need to make height calculations from the lowest floor to the ceiling itself. You should also determine the power of the uppermost floor. In this case, the thickness of the floor covering must be taken into account.

If the floor is still only rough, you should take this into account and take measurements, keeping in mind the height of the finished floor. If the opening is not as wide as expected, the concrete will have to be cut, if it is a concrete structure, to enlarge the intended opening. If the staircase is wooden, then you will have to cut off the extra parts of the beams.

Very often there is a need to increase the opening during design. Remember, there should not be any communications in the openings. In order to get the correct drawing of the stairs leading to the second floor, you will first need an exact plan of the first floor. Doors, windows, all ledges should be marked on the plan.

How to make a drawing for a staircase with winder steps? You need to specify the width of the narrowest point of such a step. It should not be less than ten centimeters. Next, you need to specify the width of the march, the number and steepness of the steps. None of the parameters can be specified arbitrarily, since they all depend on each other.

Now we need to find a suitable, comfortable width that will be sufficiently secure. When a person moves up the stairs in both directions, he should not feel discomfort, a sense of insecurity, or a narrow space. The width is the distance between the handrail, or the handrail and the wall. In order to determine this parameter, you need to know building standards.

To increase comfort, one hundred and twenty-five centimeters must be laid in the project. In the case of the location of the structure between the walls, the correct number is one hundred and ten centimeters. If the structure is attached to the wall on one side, or has two fences, the figure is ninety centimeters. If there is only one fence, eighty centimeters are acceptable. But in this case, it is not acceptable to use a ladder to carry large items. For domestic premises, or garden houses, the number of seventy centimeters is appropriate. The width should be such that the passage remains free, there is no discomfort, and the person feels safe.

If the staircase is spiral, then the maximum width must be taken into account in the drawings, one hundred and ten centimeters. The most optimal size is one hundred and forty centimeters. Width for spiral staircases is the distance between the central pillar and the edges of the steps. If the marches are directed at each other, then there should be at least ten centimeters between them.

Let's talk about what the slope should be. Steep types of stairs save space, but they are by no means a safe option. Gentle steps are much more comfortable, but they take up a lot of space. What to do. If you want to combine space saving with comfort and safety?

The best option in this case is a staircase with two flights. The most comfortable climb angles are from twenty-three to thirty-seven degrees. The steeper the stairs, the more dangerous. There is also such an option as a gentle ramp. If the slope is forty-five degrees, you can go down the stairs only by turning to face it. A slope of more than fifty degrees is only for ladders.

Now we begin to calculate the dimensions of the steps. Steps are designed depending on the steepness, as well as personal preferences of the person. Remember that it is convenient to raise your leg to a height of no more than thirty-two centimeters. But the most optimally comfortable option is a height of fifteen centimeters. It is better not to make the riser higher than seventeen centimeters.

In one march there can be from ten to fifteen steps. The width of the approach is made depending on the purpose of the stairs. The minimum you can do is twenty centimeters, but the standard is thirty-two centimeters. The most limiting number is forty centimeters. If the dimensions do not allow making the tread wide enough, then the treads will hang over the risers, this is acceptable. All steps must be the same height and width.

A staircase with a straight flight is usually laid in the middle. If the design is curvilinear, the middle line is drawn in the mind half a centimeter from the rack, or flying edge. We proceed to the calculation of the height of the passage. Clearance needs to be given special attention, comfort largely depends on this. Whatever type of stairs, the clearance should be as comfortable as possible.

If the height of the passage is five centimeters higher than the height of the person walking along it, he will involuntarily bend his head. The norm for the clearance is from one hundred and ninety to two hundred centimeters. The height of the passage must be the same for the entire staircase. Now you know how to make a safe, comfortable, and beautiful staircase.

This type of staircase will fit well into any office space. The style is very suitable for business buildings. In addition to style, such a staircase is an economically advantageous option. Stairs must meet all standards for steps, railings, and landings.

Welding work must be of high quality, taking into account all the small details. The color of the stairs is possible in any desired shade. The ladder must be made in accordance with the correct work cycle. First, measurements are made, then a project for a specific room, after manufacturing, and installation of the structure. Guarantees must be provided.

Stairs are an important part of a person's daily life. Many times a day we encounter this design. Construction work is almost always associated with the creation of a ladder structure. It connects several levels of any building. A very long time ago there was such a design as a staircase. And in our world it is a very important part of life.

There are stairs very similar in appearance to each other. But they may differ in shape, color, and design, and even the design itself. There are two main types of stairs. The first option is a marching design. It has at least one span.

Also available between the levels of the steps of the platform. The second type is spiral staircases. They are in the form of a spiral. The metal internal ladder is famous for durability, beauty. Many made their choice in her favor, and were satisfied with the result.

The entire load at the spiral staircase is directed to the supporting central post. Steps are attached to it. This type of stairs is very popular and widespread. This is due to the elegance of the appearance of such a design. The spiral staircase can also be interrupted by placing intermediate platforms. They can even serve as a level connection between floors. But the platform can only be installed if there is enough space under it in height. If the spiral staircase is made of cast-in-situ reinforced concrete, it will become too difficult to formwork. Therefore, a wooden spiral staircase is a very good option.

There are so many different options for spiral staircases. They are very different in appearance. The style and design can be completely unique. The situation is not easy with screw structures if they have a free location without a side fence. In this case, the steps will go out of the center of the rack. Therefore, the steps become a barrier, and provide a fortress for the entire staircase.

The wooden screw structure necessarily has a steel support. Such a staircase can be used in a spacious apartment, and in a cottage, and in a country private house. There are generally accepted rules.

According to them, such a design in a large house should be at least eight hundred millimeters. If we are talking about a small-sized room, then the width can be from seven hundred to seven hundred and fifty millimeters. A spiral staircase is installed anywhere in the house. It can be placed in free space, near a wall, in a corner, or even between two walls. The material for the construction must be solid wood. Pine is the most extreme option. Steps are best made from a puff type of wood.

Tier decoration

Let's talk a little about the design of stairs in private homes. Now there are a lot of private houses. They differ in volume, price, and finish. But most houses have at least two floors.

Therefore, very often the question arises of how to make the design of the structure. At the stage of building a house, materials, location, as well as the type of staircase are laid. Those who love the classics often choose wooden or stone stairs with marches. The marching design is considered a classic option. Its design provides for straight platforms, which are connected by steps. This version of the stairs is the perfect solution for any home interior.

How beautiful to arrange the tiers of the stairs? Wood is used for the construction device, this is the traditional option. In addition, wrought iron or special glass can be used. The transition to the next floor must be made in accordance with all building codes.

It should be comfortable and safe. The design of the stairs can be very different. There are so many kinds of design sides. The staircase in the house consists of a supporting structure, as well as steps. Each part also bears a load from an aesthetic point of view. Regardless of the material of construction, its tiers should fit perfectly into the overall design of the house.

Each house symbolizes the human world, it reveals a lot about its owners. The history of such a structure as a staircase began many thousands of years ago. With each new era, the stairs became more beautiful and updated. Now there are many forms and designs for decorating stair tiers.

Staircase in a U-shaped house

U-shaped structures are very common. They are used in country houses. They are also often seen in public institutions. We encounter them all the time. Such a staircase has a turn of one hundred and eighty degrees. It consists of three straight spans. Due to this, this design is considered to be particularly reliable and suitable for extreme loads.

The most popular are monolithic internal stairs. They have a very simple design, but good rigidity. Therefore, they are very strong and reliable. Concrete is poured into the construction formwork, which greatly guarantees the quality of the future structure. In country houses, stairs are often made on bowstrings. The beam becomes the basis, which is located below and on the side. This makes the staircase practical and decoratively attractive. When designing a U-shaped staircase, it is very important to ideally calculate the pivot point. The fences above should not intersect. Most often, such a staircase is located in the middle of the room. Durable and stylish!

Conclusion

So, having made such an extensive overview of the types of stairs, you can decide on your preferences, as well as opportunities. By properly designing the stairs, you can decorate your home. Moreover, if you follow all the rules during the construction of the stairs, your family will use it safely for many years.

Projects of stairs to the second floor in a private house, a plan for an internal metal, wooden spiral staircase 2 by 2 by 2 floor in a U-shaped house, how to make a metal staircase with your own hands for a summer residence - price, sketches, beautiful photos

Message

sent.

When building a house with at least 2 floors, you definitely need to think about the stairs in it. And if the house will be built with your own hands, it is logical to do the stairs as well.

Various photos of stairs help to make a preliminary choice and clearly understand what type of lift you need. But before undertaking work, carefully calculate the future design for strength and dimensions, this will save time and money, because incorrect calculations (or lack thereof) will lead to numerous alterations of the original project.

Stair types

There are a large number of different options for flights of stairs. They differ in the material of manufacture (wood, concrete or metal), the type of rise (sloping stairs, spiral, with a turn by a certain degree).

The most common is a ladder made of wood. Also often construct a staircase with a turn of 90 degrees. It is not uncommon for these two types of lifting device to be combined into one.

In case of limited space, a spiral staircase is made of metal. The screw type of lifting saves space, and the manufacture of metal increases the strength of the structure. Concrete is used for stairs in massive buildings (for example, mansions).

What to look out for

In a low-rise building, having no construction experience, it is better to order a modular staircase, a kind of designer, where all the details are sawn and numbered, and you just have to assemble them using the instructions. These are usually made of wooden stairs.

When building a staircase made of concrete, in addition to pouring the frame, you will need to perform an external finish (beautiful stone or wood materials). It's a double waste of time and money. However, for cottages of 3 or more floors, they are mandatory according to fire safety requirements.

When making a staircase for the first time, you do not need to aim at a complex structure right away. The simpler the model, the more likely it is that you will be able to successfully build this lifting device on the first attempt.

Pay attention to the angle of inclination of the stairs: if it is more than 45 degrees, the ladder will be considered attached, and you can only go down it backwards. The optimal angle of elevation is considered to be 37 degrees.

Wood as a material for construction is preferable, as it allows, thanks to its properties, to correct minor construction flaws that have arisen due to inaccurate calculations and inexperience of the contractor.

Also, after construction, the building may settle due to loose soil, as a result, the staircase can become several centimeters higher or lower than the floor, and it is easier to fix this in a wooden structure.

When constructing a lift with a turn towards it, the distance between the spans must be at least 100 mm.

Stages of construction

Answering the question of how to make a staircase to the second floor with your own hands, there are several stages of construction.

The first stage of any structure, whether it is a staircase to a house or an interfloor staircase, is the creation of a project. Particular attention should be paid to the safety of the building and its ease of use.

The structure must withstand the average weight of an ordinary person with a fair margin. Be sure to use railings!

If they are not available, another fence must be designed to ensure the safety of descent and ascent.

Consider creating a wooden staircase with stringers

After you have designed your building, you need to prepare the materials. In our case, choose boards of suitable thickness and length, prepare balusters with railings and prepare stringers. This will be the second stage of construction.

As a material for stringers, a pine board 4 cm thick is suitable. On it, we mark the steps according to the pattern and cut them out with an electric jigsaw.

Note!

We use the resulting product as a model for the second (and if the width of the stairs is more than a meter, then the third) kosour. We cut the required number of steps in size.

The third step is to assemble all the parts together. First of all, the stringers are installed in their places of permanent placement. Then, with the help of self-tapping screws, the steps are attached to the stringers.

Then, using studs, they put balusters on the steps, and handrails are attached to them. The stairs are ready!

DIY staircase photo

Note!

The front door of a private house is the face of its owner, and the street staircase plays a very important role. With a variety of modern building materials, the installation and arrangement of the entrance staircase turns into a work of art. Concrete or wooden structures with forging elements or street stairs lined with decorated tiles create not only a pleasant impression, but, with proper installation, will serve their owner for decades near the threshold of the house.

The first thing you need to know when building an outdoor staircase and is the material that is used for this type of work. Most often used:

An example of a concrete entrance staircase with a tile finish

Video from Youtube:

In fact, for the construction of an external staircase, there is a sufficient variety of building materials (for example, brick), it is enough to choose the one with the most optimal pricing policy and a long service life. But this type of stairs also differs in the form of its design. It can be:

- Screw. Often used in houses with a high base. They can have a classic shape or have more right angles.

- Rectilinear. The most common, as they make one row of steps, which does not require a large amount of building materials.

- Street stairs with a platform. Which is mounted in order to improve the appearance. For the site, it is necessary to make more gentle steps.

Of course, there are a large number of modern solutions near the house, but the above examples are the most common.

The sequence of installation of an external staircase made of concrete

As mentioned above, the most common option is an external staircase to the house, made of concrete or brick. Concrete is a durable material that is not affected by temperature changes, as well as the effects of precipitation. You should be aware that for the installation of an external staircase of this design, cement grade 400 can be used.

Drafting

Each work, especially the construction of an external staircase to the second floor, begins with a preliminary placement of the project on paper, with all actual dimensions and structural elements. The basic rules that must be taken into account when designing an external staircase:

- The design of the entrance stairs to the house must be made strictly perpendicular to the entrance doors.

- The porch cannot be poured at the same level as the floor in the house. It should be lowered by at least 5 cm.

- The sides of the stairs should not coincide with the entrance opening. They should be expanded by 10-15 cm in each direction.

- When pouring steps, it should be remembered that their number must be odd. This will help make the steps as comfortable as possible both when climbing up and when descending from the porch.

- The height of one step should not exceed 20 cm. Some owners of private houses make them smaller, which leads to too long stairs.

- A step slope of 3 degrees will create the correct plane for draining rainwater or conveniently clearing snow. If you make the slope large, then it will be too clearly felt when walking up the stairs.

Foundation

If you are going to pour the entrance stairs into the house, you should remember that its weight will be quite significant. Therefore, an appropriate foundation is needed to support the entire structure. Depending on the depth of freezing in the region, the depth of the foundation itself varies from 50 to 120 cm. The sequence for creating a foundation for an external staircase is as follows:

- Pit preparation. The hole needs to be dug a little larger than the entire structure, since the foundation is and cannot be narrower than the staircase itself.

- After the pit is dug, a layer of sand up to 15 cm thick must be poured onto its bottom and leveled over the entire surface. A layer of rubble is poured onto the sand, also no more than 15 cm.

- You can start pouring concrete or laying bricks. The proportions of the solution: 4 buckets of sand, 1.5 buckets of cement, the amount of water varies depending on the quality of the concrete - it should not be too liquid, but it should not be made thick enough either.

The presence of a concrete mixer greatly simplifies the process of pouring the foundation. After it is ready, it should be covered with an ordinary polyethylene film - this will prevent the appearance of cracks that can occur as the concrete dries. If the film is not at hand, then the solution should be watered every 1.5–2 hours.

Mounting formwork and pouring steps

Proper formwork installation will greatly simplify the process of pouring steps for the entrance stairs to a wooden house, but for this you should stock up on building materials such as boards, a building level, plastic film, self-tapping screws (nails should not be used, since they are much more difficult to get out of the formwork), a screwdriver .

First you need to mark the top point of the future staircase, for this it is enough to set aside 5-7 cm down from the threshold of the front door and make an appropriate mark with a marker. Now, with the help of boards, 2 halves of one formwork should be made, the height of which should be equal to the distance from the ground, to the very mark on the wall, at the bottom of the front door.

Further, a plastic film should be fixed on the inside of the formwork of the steps, otherwise the solution will be absorbed into the boards, and it will be quite problematic to remove them later. A good option is to treat the boards with machine oil. After the above procedures, the formwork can be installed and fixed from the outside with boards.

For the inside of the formwork, it is necessary to prepare a frame of reinforcement. Reinforcement (with a cross section of at least 10 mm) is knitted or welded into a frame corresponding to the shape of the stairs. You can make it a little lower than the plane of the steps. After pouring with mortar, the reinforcement should not remain above the level of the concrete. After the structure is ready and installed inside the formwork, you can start pouring concrete.

It should be remembered that the formwork can be removed after 24 hours, but the structure must be allowed to brew for at least 15 days. Only with this option, the solution will finally seize and, together with the reinforcement frame, turn into a single whole.

Finishing work

15 days after pouring the foundation, you can start any type of finishing work on the entrance stairs to a private house. Tiles designed for use in an outdoor environment are ideal for finishing a concrete staircase. Even with a properly constructed formwork, a concrete staircase will have some irregularities that will hide a sufficient amount of glue or special mastic.

When laying tiles on the entrance stairs, you should also not forget about the seams, which should be equal and neat. For the correct location of the seam, you should use specially designed plastic fasteners.

How to make an outdoor metal staircase

When installing a metal staircase in front of the entrance to the house, it is also necessary to fill the foundation. Only for such a design, a hole is not required for a depth of 100 or 120 cm. It will be enough to dig a hole with a depth of 70-80 cm. Otherwise, the foundation is prepared in the same way as with a concrete staircase: a layer of sand, a small layer of rubble and concrete mortar directly. After pouring, the distance to the ground surface should be at least 20 cm, this will then allow the metal channel to be laid.

Metal entrance stairs to the second floor have the following installation procedure:

- The channel used for the construction is installed on the foundation and poured with mortar. Only that part should remain on the surface, to which the entire ladder will subsequently be welded or bolted with bolts.

- must be reinforced with standard metal braces. Spacers can also be welded between the steps, which allows you to significantly strengthen the structure, making it almost monolithic.

- You can also fix the channel using the same metal corners, for the connection of which welding is used.

- The upper part of the stairs is attached to a place located 5-7 cm below the threshold in private houses. The fastening method is as follows: drill a couple of holes in the wall and insert reinforcement into it, on the edge of which metal plates must be welded. The end of the ladder is connected to these plates by means of a weld. The reinforcement in the wall can be further strengthened with mortar.

After completion of work in the house, all welded seams of the structure on the second floor must be carefully sanded, excess drops of metal can be removed with a grinder. After grinding, they begin to clean the frame and then paint it. Sheets of metal, 3-5 mm thick, are used as steps, which are attached to the frame with bolts.

Outdoor stairs made of wood

Wood is a fairly durable material for building a house, requiring careful and scrupulous processing. When choosing a tree for mounting an external staircase in private houses, you should not save money, a quality dried oak is most suitable, as a more budgetary option, you can use pine. The main indicators of the quality of the timber:

- No fungus, mold, dark spots. In the presence of a pest, the life of a tree outside the house will be reduced to several months.

- Well dried material. If the wood has not been dried, then after installation, after a short time period, the entire structure will lead to the sides. Therefore, you should choose only dry boards.

- Minimal or complete absence of cracks. Even the smallest crack can develop into a long furrow that spreads along the entire length of the board.

Even for a wooden frame, for example, on the second floor, a foundation is needed near the house. Most often, this is made in the form of small pillars, 20 by 20 cm in size and about 40 cm deep. For greater strength, after pouring the foundation, several reinforcing bars can be stuck into it. This will provide greater structural reliability.

Video from Youtube:

A wooden staircase in private homes is assembled according to the type of an ordinary children's designer. In all elements, special grooves are made that will ensure the stability and reliability of the entire structure. But it is not enough to insert several elements of the stairs into each other, they also need to be fastened with nails or simple self-tapping screws.

Having completed the construction of a wooden frame near the porch of the house, it should be sheathed with boards. Boards are attached to the frame with nails or screws. One of the main elements of each staircase is the railing, which can be very quickly prepared from an ordinary beam, which was used early for the construction of the frame. Of course, ready-made wooden balusters will look much more spectacular, but at the same time they have a much higher price.

Photo gallery of exquisite entrance stairs

In a two-story house, it is necessary to place a comfortable, safe and beautiful staircase. You can invite craftsmen or assemble from a ready-made kit, but we will tell you how to design and mount it yourself.

Types of stairs - classification by shape

Stairs to the second floor in a private house differ in their shape. Several designs are used: with marches and helical. The former can be straight 90°, 180° or 360° swivel. Screws are compact, but they are inconvenient to use, especially for young children and the elderly. Marches are convenient, but they take up a significant part of the usable area, especially straight ones. The space below them is often used as utility rooms. The easiest way to build a marching staircase.

It includes one or two marches with steps evenly spaced. Their number is 3–15 if there is more than one march. On average, 8–11 steps are arranged on each march, and there are platforms between them. If there are more stairs with one flight of steps, it is also recommended to arrange platforms in order to increase strength. Steps are open or closed, with risers. Open are convenient with insufficient width of the act.

Mid-flight stairs can be made with small turns, less than 90 °, and are called rotary. At the turn, winder steps are more often arranged instead of a platform.

Stairs with bolts are popular - long rods with threaded ends. They serve to fasten the steps and fencing the structure, which is mounted in the wall. They have a light and airy appearance, but are actually very strong and reliable. The design can be stretched over the entire wall, or it can be built compact. Due to the features of the attachment, it is located only against the wall. It can be assembled from ready-made elements, it is better to entrust the installation to professionals.

Difficult to manufacture, but take up little space, they can be installed anywhere, even in the middle of the living room. Many do just that: the staircase is aesthetically attractive and becomes a decoration of the room. Various designs of these products are known, but for two-story buildings, a model with a rack and wedge-shaped steps is better suited. The rack is attached to the floor and ceiling, and steps spiral to it. On the side there is a handrail repeating the screw shape of the product. Balusters are attached to the handrails and steps.

Materials used - advantages and disadvantages

In addition to the form, the material of the stairs plays an important role. The most affordable material with many advantages is wood. Fashion for him does not pass for centuries. Wood products are durable, beautiful, decorate the house for many years. To maintain the appearance, it is necessary to renew the decorative coating every few years. You can not use paintwork, but emphasize the structure of natural wood.

Between floors they are often arranged as a basis for attaching parts from other materials. For steps use wood, marble, glass. Bare metal is allowed for the whole structure, but contact with it in a cool room is unpleasant. Metal stairs with glass railings look beautiful - light and airy. Glass and metal are well combined with wooden parts made of beech, teak, maple, cedar.

A new word in the manufacture of stairs is the use of special impact-resistant glass. It can withstand heavy loads, it is completely safe to use. The design with a glass staircase only wins with its grace and elegance. It is very effective to use neon bulbs for illumination.

We select materials in accordance with the chosen interior style. Metal is suitable for classic minimalism and baroque. Modern and Scandinavian styles prefer glass. Concrete, marble are typical for the loft style, eclecticism. Concrete is exceptionally durable, specialists make amazing things of incredible beauty out of it.

Product features - what parts does the staircase consist of

The design of the stairs includes many details. Some of them are necessarily present in all products, others are specific, used only in some types. Even the simplest interfloor construction is not complete without supports and steps. The step has two parts: one of them is located horizontally, the other is vertical. The horizontal one is called the step, the vertical one is called the riser. The risers play the role of a support for the tread, but in some cases they do without them.

Marches from a number of steps are mounted on supports. Two of their types are used: bowstring and kosour - beams that differ in location. The bowstring is placed so that it fastens the steps from the end, and the stringer supports from below. Supports are made of thick material: 50–70 mm. The stringers are saw-shaped, steps are placed on the horizontal platform, and risers are placed on the vertical platform. There may be one central one, when the steps rest on the wall, or two. The grooves in the bowstrings for the deed and the risers are cut according to the pattern. Beams are pulled together with wooden or metal strands.

Stairs almost always have railings, although they are not required. But for older people, they are simply necessary. The railings are complemented by balusters - vertical supports between them and the steps. They are often not just a functional element, but play the role of a decorative ornament. They are made from different materials, different shapes. If there are small children in the house, balusters are required to protect them from accidental falls.

For individual structures, details are used that are specific only to them. Spiral staircases cannot do without a rack. It is made of steel pipe or wood, serves as the basis for the entire product. On some models, bolts are used to fasten the steps to the wall - special threaded pins.

Preparation for design - the choice of type, fastening, dimensions

Starting manufacturing, they first decide which type of product is better to use, taking into account the existing conditions. For a private house, options for stairs are possible:

- 1. Straight lines - easy to calculate and install, convenient to use. Requires a lot of space.

- 2. Rotary with two or three marches and platforms between them. Staircase turns 90, 180 or 360 degrees to save space.

- 3. Rotary winders - similar to the previous version. The role of the platforms is played by steps, additionally up to 2 m 2 of area is saved.

- 4. Screw - very compact, but not very convenient to use. Recommended for rooms with a small area.

We continue the construction with the choice of fastening:

- bolts - mounted on the wall, the design is elegant, but can withstand significant loads;

- rack - used in spiral structures or rotary as an additional fastening;

- bowstring - steps are installed in the internal grooves of the beam, the ends are closed;

- kosour - the upper part of the beam has a figured profile for supporting steps on it, the ends are open.

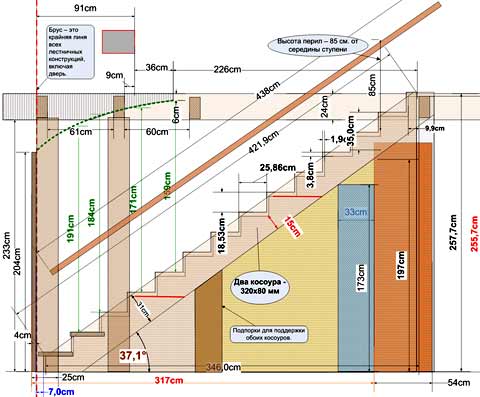

- the height of the opening between the finishing floors of the first and second floors;

- the width of the opening, which, in addition to being rectangular, can be round, oval, which is determined by the version of the product;

- height from the floor on the ground floor to the ceiling.

Calculations - building codes and formulas

We will show how to design a product using the example of a marching staircase. In order not to make mistakes, you should familiarize yourself with building codes for the construction of stairs. They have been developed over many years of practice and guarantee the safety and ease of use of the product. The main rules that should be followed when performing all calculations in the future:

- the slope of the marches is not more than 45 °;

- not less than 90 cm wide;

- the height of the steps does not exceed 20 cm, the depth is not less than 25 cm;

- the dimensions of all steps are the same;

- fence with a minimum height of 90 cm;

- the location of the balusters in a house with small children after 10–12 cm.

In rotary structures, the dimensions of the inter-march platforms are at least 75 cm, and the winder steps, if used instead of platforms, are at least 20 cm wide.

Further work on the project continues on paper. We draw a plan of the first floor with an indication of all dimensions. On it we mark various ledges, niches, windows, doors, communications. When designing, we try to ensure that they do not overlap with load-bearing structures. We indicate the place of the beginning of the march on the first floor and exit to the second. We try to put down as many dimensions as possible, which will facilitate the installation of the product in the future.

Then we work with the measurements that we performed earlier. We calculate the number of steps: the height of the opening (the distance between the floors of the first and second floors) is divided by the height of one supen. Example: opening 290 cm, step 18 cm. Dividing, we get 16 steps.

We find out the length of the product: we multiply the number of treads (we have 16) by their optimal depth - 25 cm. As a result, we get 4 meters. The length is such that in a small room there may not be enough space. If divided into 2 marches of 8 steps, it will be necessary, taking into account the minimum platform size of 75 cm, almost half the area.

Finally, we find out the length of the supports, it doesn’t matter whether it is for stringers or bowstrings. We apply the Pythagorean theorem: c 2 \u003d a 2 b 2. In this case, a is the length of the product (4 m), b is the opening (2.9 m). It is required to find out c - the length of the supports. We add squares a and b: 16 8.41=24.41. We extract the square root of 24.41, we get 4.94 m - this is the required length of one support. If you do 2 marches, the length will be 3.5 m.

All calculations are applied to the drawing.

A simple solution - a straight marching staircase on stringers

It is easier to mount it yourself on stringers with one straight march. True, at the base, its length will be at least 4 meters, and the span will exceed five. But if the size of the room allows, it will become a decoration of the house. The product calculations are given above, we will tell you how to make parts and assemble the structure with your own hands.

For stringers, we take a dry blank from a hardwood board. We draw a template on cardboard or thin plywood, taking into account the shape of the protrusion and the angle of inclination. We apply it to the beam and cut the mount. At the ends of the stringers, we cut out the grooves for fastening to the upper floor beam and the lower beam. We process the grooves with sandpaper to eliminate burrs. In a prepared place on the floor, we attach the support beam to the anchor bolts. To attach the stringers to the ceiling beam, you can install anchors on it or simply join by cutting.

For the manufacture of a deed, we use a dry board with a thickness after processing of 35 mm or more, 20 mm is enough for risers. The risers can be installed not along the edge of the step, but deepened a little, then a wider board should not be cut. Alternatively, it is possible not to use risers, the design will be easier. We select the length of the parts taking into account the width of the march plus the railing. We cut off the edges on deeds, grind the workpieces. First, a riser is attached to the stringers, then an act. We use wood glue and self-tapping screws. Glue is needed so that the stairs do not creak when walking.

Let's start making railings. They consist of handrails and balusters. For balusters we use square bars, if possible, we grind them on a lathe or buy beautiful carved ones. They are mounted on steps, usually one baluster each. We fasten with self-tapping screws, the caps of which are closed with decorative plugs.

The assembly is over, it began to apply paints and varnishes that will simultaneously protect the tree from moisture and perform decorative functions. First, we grind the assembled product again, removing the smallest burrs and burrs. For painting, we use paint, varnish or a protective colorless composition, tinting agent. Paint, varnish, we choose those that do not have the properties to create a smooth surface. It is easy to get injured on slippery steps.

Spiral staircase - a turnkey solution with drawings

A spiral staircase for self-production should be easy to install and be safe. The width of the steps plays a decisive role in the prevention of injuries. They are winder in spiral structures, there are no intermediate platforms. There are several ways of fastening: on the walls, on the stringers, on the bolts. They are quite complex for calculations and installation. The best and most reliable way for a home is to mount it on a rack.

The structure is made of wood or metal. The wooden product, varnished, looks very beautiful, gives comfort. Any solid wood species can be used. For handrails, it is better to use a combination of wood and metal. For steps, in addition to wood, metal, artificial marble, and glass are also used. A metal pipe is perfect for a rack. Steps are attached to it with couplings, bolts or welding, depending on the material of the steps. Brick, concrete, wood are also used for the central rack. The main thing is that it can withstand the load.

It should be observed so that it is comfortable and safe. One of the most important is the distance between the step on which the person stands and the one above his head. In order not to touch the head, it should be 2 meters. The width of the staircase is chosen not less than 90 cm, with dimensions of more than 1.5 m along the edge, the installation of a stringer will be required. The stairway should be 10 cm wider than the diameter of the stairs at each end so as not to scratch your hands when using the railing when exiting to the second floor. Below are the drawings for calculating the spiral staircase

The best type of spiral staircase is with a metal central support made of a pipe with a diameter of 50 mm. To your attention step by step instructions for its manufacture:

- 1. We install the support vertically, checking with a plumb line and level. We fasten to the wooden floor with bolts, using fasteners, pour it into the concrete. Mounting in this way will ensure the reliability of the entire product.

- 2. We take another pipe of a slightly larger diameter in order to cut sleeves from it. We cut them perpendicularly with a height of 23–26 cm. The sleeves should be tightly placed on the rack. If it was not possible to select a pipe of the required diameter for the sleeve, rings for sealing can be welded.

- 3. Then we proceed to the manufacture of steps. They must be the same. To achieve this, we make a conductor from chipboard and a pipe equal in diameter to the sleeve.

- 4. We lay the profile pipe in the conductor and connect it by welding - the base for the site has come out. Then we connect all bases with sleeves by welding at the same distance from their edge. To withstand the distance, we use a conductor.

- 5. We weld a bracket to the lower part of the base from the front side, equal in height to the distance between adjacent steps. You can make and weld risers, which is somewhat more difficult.

- 6. We string the sleeves with metal platforms on the rack, unfold them like a fan. We weld the bracket going from the top step to the bottom.

- 7. We weld sleeves together, install railings with balusters. The method of fastening depends on the material from which they are made. It is possible to use metal, wood, plastic or a combination of them.

- 8. Having collected all the elements, we clean the welding seams, cover the entire structure with nitro enamel. We cover the wooden parts with paint, if the texture is rich - with a colorless varnish or tinting agent.

It is not difficult to create interfloor stairs for a person with elementary construction experience, and the pleasure from the result will be great.

To understand how best to place a wooden or metal structure on the second floor and use the space under it, you need to figure out what structures exist in principle.

The staircase in an apartment or house differs in its configuration quite strongly. And depending on the total area of \u200b\u200bthe room, one or another design is chosen for the second floor.

The simplest option is considered to be a wooden straight single-flight staircase with comfortable steps that climb to the second floor without uncomfortable turns. This design is characterized by large dimensions, but also great safety.

A variant of such a staircase design is also considered the easiest to create with your own hands. The most important and obvious disadvantage is its bulkiness. However, in order to save space in the house and not to burden the interior, various modifications of the structure are used. It may have a twist. Perfectly saves the space of the house, the option of a staircase structure to the second floor with a turn of 90 degrees. It can also be made at an angle of 180 degrees. The only nuance that should be taken into account is that in this case the structure will have to be equipped with winder steps, and this will slightly complicate the creation of stairs with your own hands.

Where and how to arrange the stairs to the second floor depends on its elements. Usually the design has steps, a frame and a railing. Frames may vary depending on the design of the stairs and the material of their manufacture. They are made in the form of stringers, bowstrings or support pillars, if these are spiral staircases.

The frame in the form of stringers is two beams in the form of a ladder, on which steps are installed. They can also be straight, in which case the steps are fixed to them with the help of fillies. Stringers in the form of a ladder are perhaps the most common option when creating a wooden staircase structure. Such frames are the most ergonomic, so if you want to place a mid-flight ladder, then you need to use them in the design. However, it is important to keep in mind that they are less durable than, for example, bowstrings or braids with fillies. They are not suitable for large stairs.

A more compact design will be obtained by creating a flight of stairs on one central stringer. Usually it is made of metal. Span planning:

In addition to stringers, there is another option for fastening steps - bowstrings. This frame consists of two beams, usually made of wood, into which steps are inserted into specially made grooves. Stairs to the second floor on bowstrings take up a little more space than on stringers.

If there is not enough space in the house, then spiral staircases will be a good option. Their structures are equipped with winder steps leading to the rooms on the second floor along a pre-calculated radius. It is rather difficult to create it with your own hands, since a serious and complex calculation of the stairs in the house is required. But it is this option that is preferable to place in a house with a small area. Spiral staircases have another advantage over straight flight of stairs: they look very nice and can become a real decoration of the living space. A support column with winder steps fixed on it serves as a frame. Ideas on how to plan the layout of spans:

The staircase on the bolts is a successful combination of the positive qualities of a straight and a spiral flight of stairs. This design is a marching version, the steps of which are attached to the bolts. Usually it does not have a frame or is equipped with it only on one side.

What to do when you want to save space in a small house and at the same time make an interesting version of the design of stairs to the second floor with your own hands? You can pay attention to the design of the tree "duck step". It can be located even in very small spaces, because it allows you to combine safety and ease of lifting even with its steep slope. This is achieved due to the special structure of the steps, one part of which is created narrow and the other wide.

What determines the compactness of the ladder structure?

In addition to the competent choice of the construction option, the correct calculation of the stairs in the house, in which it will be reliable and compact, can help save interior space.

How convenient it will be to place it in the house depends on the angle of its inclination. The smaller it is, the more compact the design, but at the same time, the more dangerous it is to lift. The most comfortable angle of inclination is considered to be 30-40 degrees, but in this case the design of the flight of stairs will take up a lot of space. Alternatively, make it with a 90 degree angle and place it next to the wall. However, if you create a goose step staircase with your own hands, then it may well be located in the house at an angle of 55-60 degrees.

The width and height of the steps of the structure can also determine the convenience of the location of the stairs in the interior. But in this case, it is worth remembering that there are ideal parameters that determine the convenience of lifting. The optimal step height is 17 cm, and the width is 29 cm.

If you are going to place a straight flight of stairs in your house, you will need straight steps, which are very easy to do yourself. To save space, when spiral staircases or straight stairs to the second floor with a turn are more suitable, you will need to know how winder structures are made. These elements differ in that their width is not the same, and in shape they resemble a trapezoid.

The width of the flight of stairs should not be less than 80 cm. The optimal size is a width equal to 90-100 cm. Anything wider will eat up the usable space of the house. Too narrow a march will be inconvenient and not safe for climbing.

How to arrange the stairs in the house?

To understand how much space the structure will take, it is necessary to make a competent calculation of the stairs and find out how and where it is better to place it.

For example, screw structures with winder steps will occupy an area equal to its diameter.

When calculating, it is necessary to find out how many steps the structure will have. To do this, its height must be divided by the height of the steps. The height of the structure is equal to the sum of the distance from the floor to the ceiling of the first floor and the ceiling.

If the length of the staircase structure is too large, then it will be very difficult to fit it into the interior of the house. To do this, it will need to be divided into two parts and make a turn with winder steps or a platform. In this case, the length of the structure will be equal to the sum of the distance between the marches and the product of the number of lifting elements and their length. The calculation of the staircase with a turn also includes the width of the overall structure, which is the sum of the distance between its two parts. This distance should not be less than seven centimeters.

In total, you can understand how much the structure will take up space in the house and how best to arrange it, by calculating its area. To do this, the found values \u200b\u200bin the form of length and width should be multiplied.

Naturally, it is more convenient to place the structure leading to the second floor in the hall of the house. However, not every home is spacious. If the hall is large, then the stairs in a private house can be made longer and wider. In a small space, it is better to place it near the wall in the corner of the room. In this case, the design on the bolts will be a good option in terms of ergonomics and interior design. It is fixed to the wall without taking up much space.

For those who consider the staircase not only in terms of convenience of location, but also the teachings of Feng Shui, you can also highlight some of the rules for its installation.

Firstly, the lifting structure should not be located in the center of the room and not in front of the entrance, but away from it. This is due to the fact that with this arrangement of the structure, energy flows can freely move around the country house.

Secondly, on the second floor, the structure should not rest against the door. In extreme cases, the door simply should not be closed.

Thirdly, Feng Shui experts advise placing the structure in the southwest, west or south. It is forbidden to build it in the northeast, which can provoke a loss of money.

If Feng Shui is not a useful instruction for you, then screw structures will look especially good in the center of the hall.

Usually the stairs leading to the second floor are located in the corridor. In the living room, it will look relevant only if the room is really large. Otherwise, it will take up useful space, which will make the room crowded. On the other hand, this does not apply to expensive and beautiful stairs, the purpose of which is to decorate the interior. The location of the building should be thought out to the smallest detail.

A lifting structure in an apartment is not common, but if the living space consists of two tiers, then you cannot do without it. In an apartment, it is better to use lightweight options that will save space as much as possible. Suitable ladders on the bolts or narrow march options on the stringers. It should fit perfectly into the interior of the apartment, since usually in such a living space the overall design is formed from each building or thing in the apartment.

With its location, it is important to consider the safety of the ascent. It is connected not only with the correct calculation of all its elements, but also with additional measures that need to be taken. For example, if the building will be located in a rather dark side of the house, then it is important to consider lighting. Although the best option would be its location by the window. In the evening, you can highlight the stairs with LED strip. It adds color to any interior.

When organizing the safety of stairs, it is important to consider the material from which it is made. For example, if the steps are made of metal or glass, then you can easily slip on them. Therefore, it is best to put special silicone liners on them. Wooden structures are often carpeted.